Company News

Pay attention to the selection of universal testing machines

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

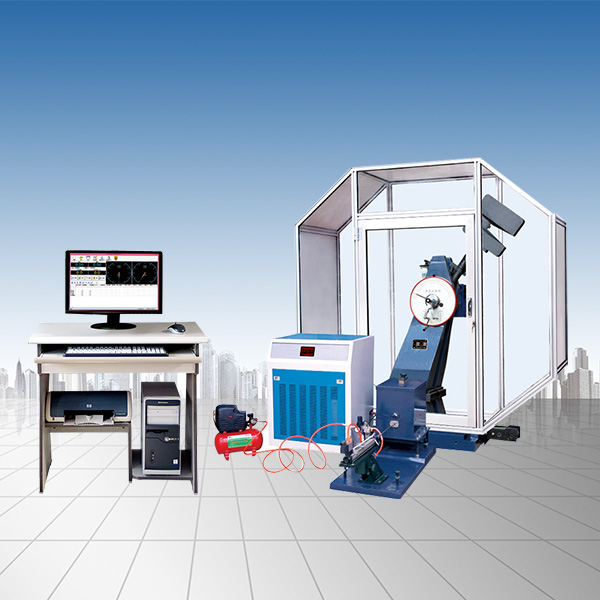

Universal testing machineYou need to pay attention to the selection, because it directly affects your work efficiency issues, the following isJinan Hengsi Shanda Instrument Co., Ltd.For your specific introduction:

Because flexible packaging materials are important for polymer polymers or their coherent materials, as mentioned above, the elongation of polymer materials is much better than that of metals, fibers, wood, boards and other materials, the tensile machine for detecting polymer polymers has a certain difference from the tensile performance detection machine for the usual material. It is especially important to pay attention to the effective stroke of the electronic universal material test machine and the sample fixture.

When conducting tensile tests, the size of the sample used is of course small, but the elongation of the material is widely and relatively high. Therefore, it is necessary to use the tensile performance of flexible packaging materials to equip a universal material testing machine with a large stroke. Otherwise, the operation of the fixture may exceed the stroke limit and cause equipment damage.

It should be noted that in the calculation of elongation, we only collect the elongation between the two markers on the sample. The markings are drawn on the sample prepared by printing or manual methods (the increase in markings will not affect the sample), and what is the distance between the markings? Most of the distance given by different scales have certain differences, and in the unified standard, different sample sizes are often given for different materials, so the distances between the markings are also different. However, this is conducive to detecting materials with extremely large or very small elongation and obtaining accurate test results. For plastic films, the spacing between the markings is usually between 25 and 50 mm.

Since the sample is deformed and elongated in the tensile test is not only within the markings, any sample between the two fixtures will obtain different levels of tensile deformation. In the standard, the initial distance between the fixtures and the marking distance should be within 80-115 mm. If the samples between the two fixtures can maintain the same elongation and assume that it is 500%, the effective stroke of the tensile tester must be 480-690 mm. If it is a sample with an elongation of 1000%, the effective stroke of the tensile tester is at leastThe 880mm talent guarantee test is deformed.

Universal testing machineTensile function of polymer

When used as a material, polymers are required to have the necessary mechanical properties. It can be said that for the majority of polymer utilization, the mechanical properties are more important than the rest of the sensitivities. Polymer polymers have mechanical properties with a wide range of variability in all known materials because polymers are composed of long chain molecules and their molecular activities have obvious relaxation characteristics.

For example, polymer materials have a considerably high elongation, the elongation of breakage of individual PEs is between 90% and 950% (of which linear low-density polyethylene LLDPE is higher), the elongation of local materials can be above 1000%, and the elongation of general polymer materials is between 50% and 100%. Usually, hot compressed films and stretched films are required to have higher tensile properties of materials.

Because flexible packaging materials are important for polymer polymers or their coherent materials, as mentioned above, the elongation of polymer materials is much better than that of metals, fibers, wood, boards and other materials, the tensile machine for detecting polymer polymers has a certain difference from the tensile performance detection machine for the usual material. It is especially important to pay attention to the effective stroke of the electronic universal material test machine and the sample fixture.

When conducting tensile tests, the size of the sample used is of course small, but the elongation of the material is widely and relatively high. Therefore, it is necessary to use the tensile performance of flexible packaging materials to equip a universal material testing machine with a large stroke. Otherwise, the operation of the fixture may exceed the stroke limit and cause equipment damage.

It should be noted that in the calculation of elongation, we only collect the elongation between the two markers on the sample. The markings are drawn on the sample prepared by printing or manual methods (the increase in markings will not affect the sample), and what is the distance between the markings? Most of the distance given by different scales have certain differences, and in the unified standard, different sample sizes are often given for different materials, so the distances between the markings are also different. However, this is conducive to detecting materials with extremely large or very small elongation and obtaining accurate test results. For plastic films, the spacing between the markings is usually between 25 and 50 mm.

Since the sample is deformed and elongated in the tensile test is not only within the markings, any sample between the two fixtures will obtain different levels of tensile deformation. In the standard, the initial distance between the fixtures and the marking distance should be within 80-115 mm. If the samples between the two fixtures can maintain the same elongation and assume that it is 500%, the effective stroke of the tensile tester must be 480-690 mm. If it is a sample with an elongation of 1000%, the effective stroke of the tensile tester is at least

Universal testing machineTensile function of polymer

When used as a material, polymers are required to have the necessary mechanical properties. It can be said that for the majority of polymer utilization, the mechanical properties are more important than the rest of the sensitivities. Polymer polymers have mechanical properties with a wide range of variability in all known materials because polymers are composed of long chain molecules and their molecular activities have obvious relaxation characteristics.

For example, polymer materials have a considerably high elongation, the elongation of breakage of individual PEs is between 90% and 950% (of which linear low-density polyethylene LLDPE is higher), the elongation of local materials can be above 1000%, and the elongation of general polymer materials is between 50% and 100%. Usually, hot compressed films and stretched films are required to have higher tensile properties of materials.

Recommended productsPRODUCTS