Company News

What are the 10 aspects to maintain the electro-hydraulic servo universal test machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

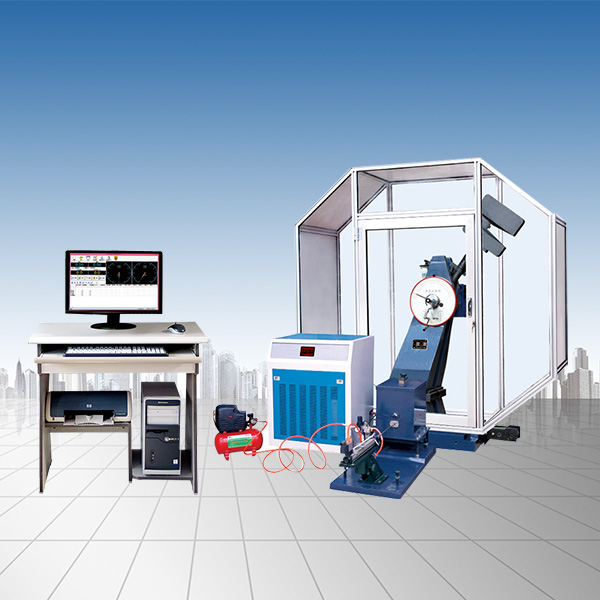

Electro-hydraulic servoUniversal testing machineIt is widely used in the tensile, compression, shearing tests of metal materials, but when working, you must always pay attention to the maintenance of the instruments for high-performance testing machines. Only in this way can the test machine be used for a long time and reduce unnecessary losses. So how to maintain the electro-hydraulic servo universal testing machine? The following are the things to note for Hengsi Shanda Instrument Co., Ltd.:

1. Hydraulic oil: It is necessary to reflect the fluid level of the fuel tank frequently and replenish oil in real time. It is usually used2000to4000Change oil once a hour, but the main thing is that the oil temperature must not exceed70℃, exceeds the oil temperature60℃The cooling system must be turned on

2. Filter: For filters without infarction indicators, usually6Change it every month. Regarding filters with infarction indicators, they must be kept in place from time to time and must be changed immediately after the indicator alarms.

3. Accumulator: Some electro-hydraulic servo universal testing machines are equipped with energy accumulators, which must ensure that the pressure of the accumulator is in a normal task state. If the pressure is found to be insufficient, the pressure needs to be immediately increased. Only nitrogen is allowed to be charged to the accumulator.

4. Regular inspection of components: All signal installations such as pressure control valves, flow control valves, pump conditioners, pressure relays, stroke switches, thermal relays, etc. must be reflected on time

5. Cooler: The scale accumulation of air-cooled coolers must be liquidated on schedule. If water-cooled coolers are used, check whether there is any cracking and leakage of the cooling copper pipe.

6. Cleaning and cleaning: Some dust will not be prevented during the experiment, such as oxide scales, metal debris, etc. If it is not cleaned in real time, it will not only wear, scratch, etc. on the surface of certain parts, but more serious if these dust enters the electro-hydraulic servo.Universal testing machineHydraulic system will cause severe results such as infarction valve holes and scratching the piston's appearance. Therefore, cleaning after each use is very important, and the cleaning of the test machine must be kept clean.

7. Use appropriate fixtures to complete the response experiment, otherwise the experiment will not be successful, but also damage the fixture: the electro-hydraulic servo universal test machine is usually equipped with fixtures that are standardized samples. If you want to make non-standard samples, such as steel strands, overlapping steel fines, etc., you must add the fixtures that are suitable for phases. There are also some super hard materials, such as spring steel, etc., and you must use extraordinary materials, otherwise the fixtures will be damaged.

8, locally applied smooth oil on the screw and transmission of electro-hydraulic servo universal testing machine to avoid dry friction

9, The fasteners of the electro-hydraulic servo universal testing machine must be locked on time: the vibration after the sample is broken often causes some fasteners to loosen, and inspection must be carried out on time (about 30 task days for normal use) to prevent large losses due to loosening of the fasteners.

10. Other reflections: Be alert and pay close attention to details, so that you can detect signs of change as early as possible and avoid becoming major changes. This is especially true when the equipment starts to be put into operation. Always pay attention to unexpected leakage, pollutants, component damage, and abnormal noise from pumps, couplings, etc.

The above is provided by Hengsi Shanda InstrumentsElectro-hydraulic servo universal testing machineMaintenance points will help you use it better.

Recommended productsPRODUCTS