Company News

How to operate the steel bar bending test machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

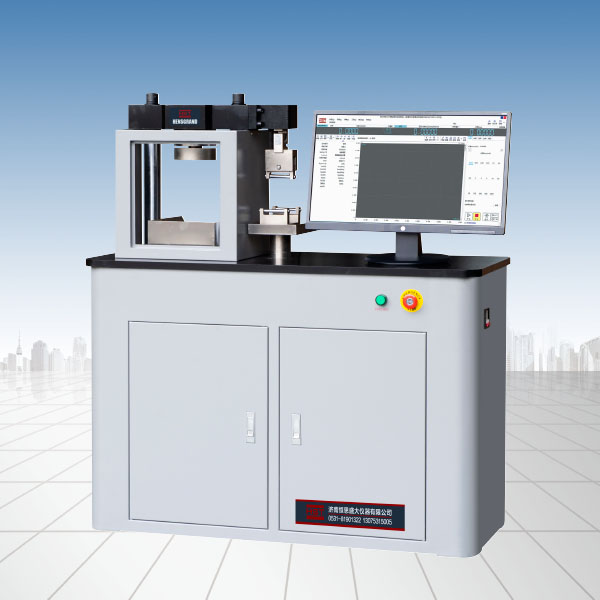

How to operate the steel bar bending test machine

Everyone is very familiar with steel bars, but the bearing capacity of steel bar bending performance still requires professional equipment to detect.Testing machineNew users may not be familiar with the operations, so the manufacturer will take you to learn about it:

1. Check the mandrel, the stopper and turntable should be free of damage or cracks, the protective cover is securely tightened and reliable, and the operation can only be carried out after the airplane is running normally.

2. Check whether the mechanical performance is good and the workbench and bending machine table are kept level; and prepare various mandrel tool barriers.

3. Install the mandrel, forming shaft, iron stop shaft or variable stop frame according to the diameter of the processing steel bar and the requirements of the bending machine. The diameter of the mandrel should be 2.5 times the diameter of the steel bar.

4. When bending high hardness or low alloy steel bars, the diameter should be replaced according to the mechanical nameplate and the corresponding mandrel should be replaced.

5. RebarBending test machineDuring operation, insert one end of the steel bar that needs to be bent into the gap provided by the rotary wheel fixing, and fix the other end close to the fuselage and press it tightly with your hands. Check that the fuselage is fixed and can be activated only if it is installed on the side that blocks the steel bar.

6. When bending steel bars, it is strictly forbidden to process steel bar diameter, number and mechanical speed that exceeds the specified machinery.

7. It is strictly forbidden to replace the mandrel, change the angle, speed adjustment and other operations during operation, nor should it be refueled or cleared.

8. It is strictly forbidden to stand people within the working radius of the bent steel bars and on the fuselage without a fixed side. The bent semi-finished products should be stacked neatly and the hooks should not be facing upwards.

9, when the turntable is changed, it must be performed after a steady stop.

10. After the work is completed, the site is cleaned, the machinery is maintained, and the power is cut off and lock box is closed.

More detailsMaterial testing machineAll information is in Jinan Hengsi Shanda Instrument Co., Ltd.

Recommended productsPRODUCTS