Company News

Common problems encountered by metal tensile testing machines

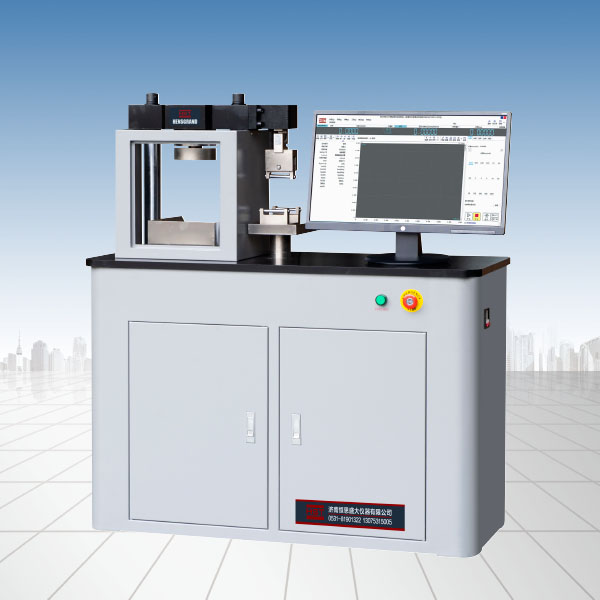

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

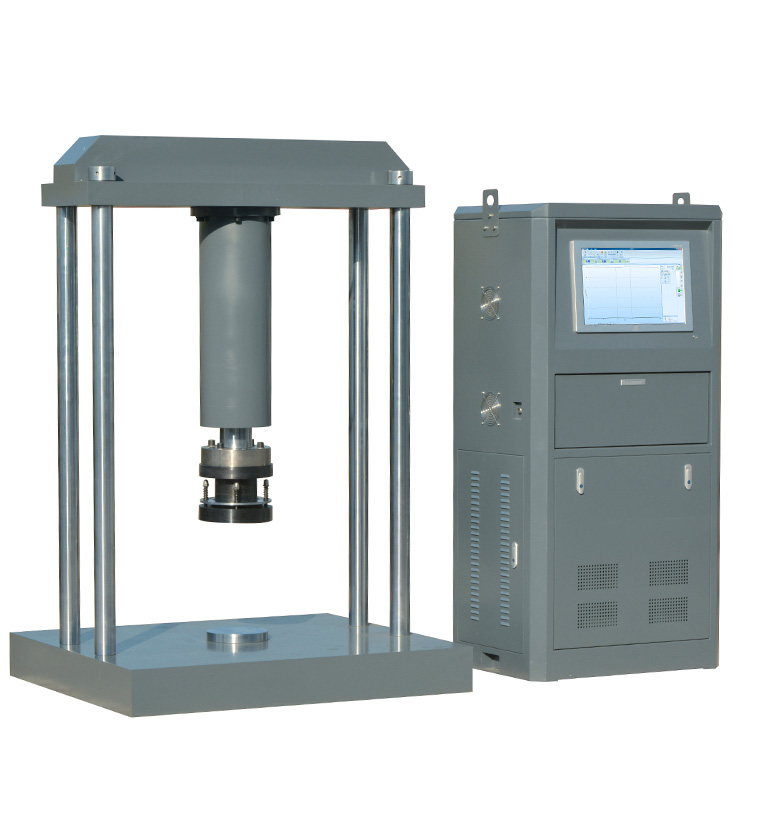

The strain rate should not exceed 0.0025/s in the plastic range and up to the specified strength (specified non-proportional extension strength, specified total extension strength and specified residual extension strength). ". There is a very critical problem here, which is the problem of the switching point between stress velocity and strain velocity. It is to switch from stress velocity to strain velocity at the end of the elastic section. During the switching process, it is necessary to ensure that there is no impact or force loss. This is theTension testera very critical technology.

The second is the timing of clamping, tracking and removal of the extensometer. For the tensile test of steel, if the total elongation (Agt) under force is required, the extensometer must be tracked and then removed. For samples with little impact after being pulled out, the extensometer can be directly tracked to the sample break; however, for samples with a large tension, the method is to start to keep the beam position unmoved after the tester stretches to the force, and then pull the sample off after removing the extensometer. Some clamps will generate an initial force when clamping the sample. You must eliminate the initial force before clamping the extensometer. In this way, the gauge clamped by the extensometer is the original gauge distance of the sample in a free state.

MoreMaterial testing machineAll information is in Jinan Hengsi Shanda Instrument Co., Ltd.

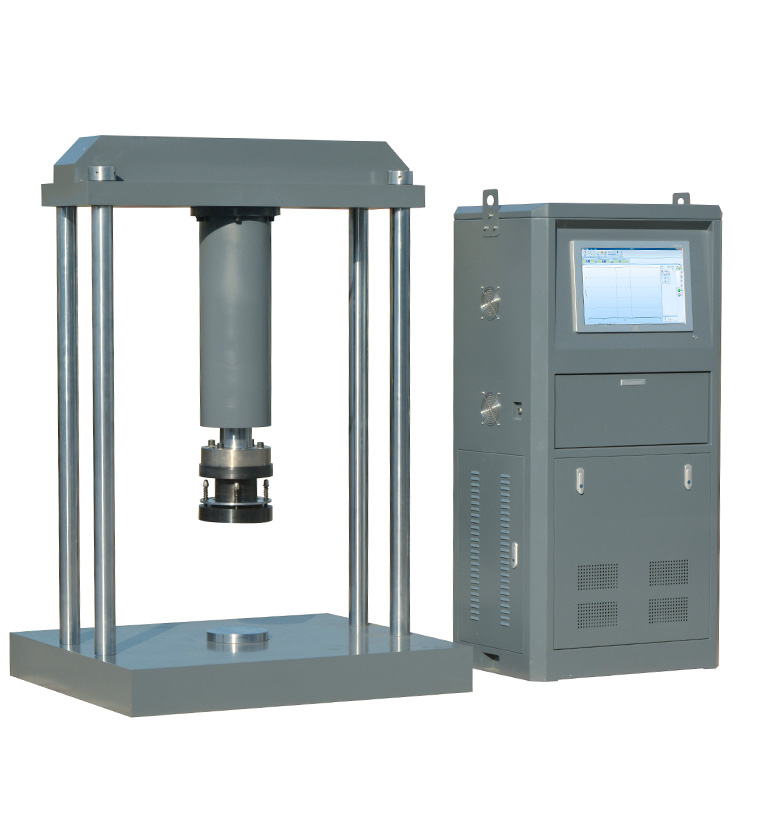

Recommended productsPRODUCTS