Company News

Introduction to the method of selecting metallographic specimens

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Metallographic microscopeIt is a product in the testing machine industry. The following are some methods for selecting samples for metallographic tests:

1. Commonly used equipment and materials for sample preparation

During the preparation of metallographic samples, water sandpaper with better texture is commonly used for coarse grinding, while metallographic sandpaper with fine grinding is used for fine grinding; p-2 type metallographic sample polishing machine is used for mechanical polishing, and most of the polishing fabrics are navy, and the polishing powder is grinding cake and Cr2O3 powder.

2. Sampling

2.1 Sampling Principle

According to the requirements of microstructure analysis, analyze the processing characteristics of sample materials or the bearing and failure characteristics of parts, as well as related technical standards and technical agreements.

2.2 Sampling methodMaterial testing machine

(1) According to the processing characteristics of sample materials

Inspection items such as forged, decarbonized, microstructure, meshed tissue, graphite and cracks in carbon tool steel and spring steel are sampled on the cross-section of the material; inspection items such as non-metallic inclusions, liquid analysis, strip tissue, white dots, carbide inhomogeneity, and ferrite equality are sampled on the longitudinal cross-section of the material; items that need to be inspected by heat treatment, such as essential grain size, intergranular corrosion, strip tissue, mesh tissue, carbide inhomogeneity, etc., can be performed according to relevant regulations or standards; castings are sampled at the center or center of the material.

(2) According to the bearing and failure characteristics of parts

Samples from the failed and intact areas were cut for analysis and comparison.

(3) According to relevant regulations on sampling special parts

For example, when sampling carburizing parts of automobile gears, usually the martensite and residual austenite detection sampling site are in the corners of the tooth surface; the center part special body detection sampling site is in the center where 1/3 of the height of the tooth; the carbide detection sampling site is at the top corner of the tooth; the surface decarburizing layer sampling site is at the root of the tooth.

The sample size side length is 10-15cm, and it is cut with a grinding wheel or electric spark cut; for large materials, after flame cutting, the heating end needs to be cut off at least 20cm, the heating influence area should be removed, and then the qualified size sample is cut with a grinding wheel or electric spark cut.

2.3 Sampling mark

Number prepared samples

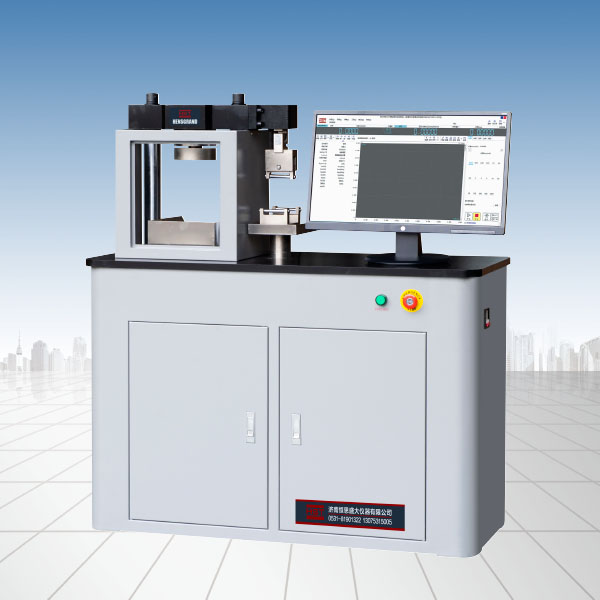

MoreMaterial testing machineAll in Jinan Hengsi Shanda Instrument Co., Ltd.

- Previous article:The tension test machine corrects the speed and force value

- Next article:Use of 7-point maintenance balance

Recommended productsPRODUCTS