Company News

Detailed understanding of the implementation specifications of torsion test machines

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The fixture of the test material specimens is very important. When clamping, first pierce the sample into the end of the static chuck (one end with the sensor), and then adjust the moving chuck of the test machine to allow the sample to easily enter the moving chuck. Be careful not to twist the chuck after loading the sample.

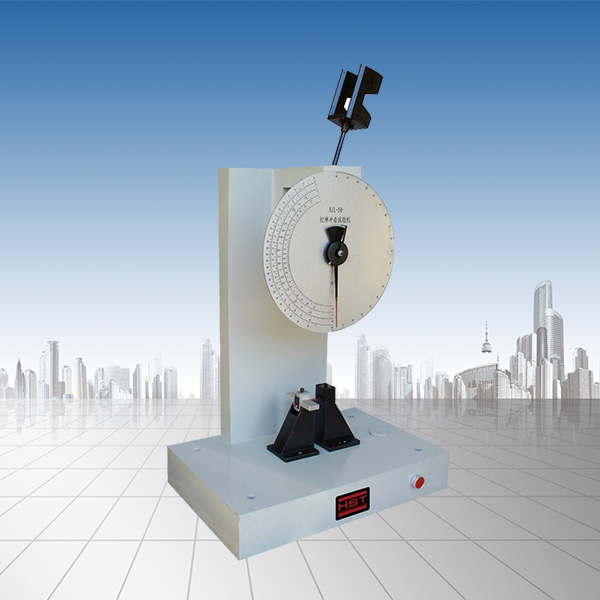

Torsion test machineIntroduction to the primary structure:

The torsion test machine is composed of a fully digital AC servo drive system, a computer control, data acquisition and disposal system. The loading speed of the entire experimental process is unimpeded and unchanged. The measurement of data is composed of torque sensors, photoelectric encoders, etc. The torque sensor collects the torque generated by the sample, and the torque angle generated by the photoelectric encoder collects the sample; when the shear modulus of the material is required, a change meter must be added. The experiment is controlled by the computer, data disposal and output the consequences.

Torsion test machineImplementation specifications:

JJG269-2006 Torsion Test Machine

GB/T10128-2007 Metal materials room temperature change experimental method

JB/T9370-1999 Torsion Test Machine Skill Prerequisite

Related technical information:Tension tester

Label:Universal testing machine,Hydraulic universal testing machine,Tension tester,ImpactTesting machine, twisting test machine, material test machineRecommended productsPRODUCTS