Company News

Causes affecting the test force value of the impact test machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Causes affecting the test force value of the impact test machine

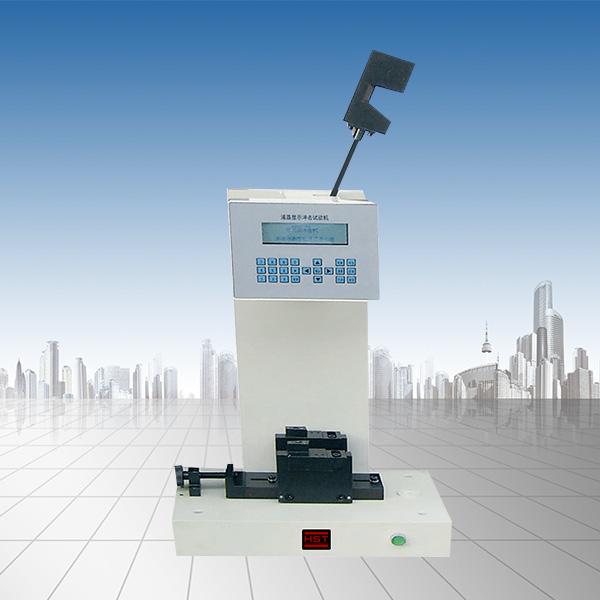

PurchaseImpact testing machineWhen purchasing, users first consider the quality of equipment, after-sales service, price and other factors. It is important to pay attention to the quality, performance and component composition of the equipment. Our company's technicians understand the factors for the test results of the impact machine:

Factors related to the processing and preparation of sample blanks and specimens

Cutting of sample billets: When cutting impact sample billets in different directions and positions of various products, different test results will be obtained, especially for different positions of strip steel, profile steel and steel plate with larger cross-sectional sizes, the Ak value varies greatly. For example: (1) The impact absorption work difference is obvious in the middle of the round steel, at 1/4 of the diameter and the surface. (2) Take samples along the steel plate rolling direction (longitudinal sample), and open gaps in the rolling direction, and the Ak value is higher; take samples perpendicular to the steel plate rolling direction (transverse sample), and leave gaps in the rolling direction, and the Ak value is lower. Therefore, the cutting of impact sample should be carried out according to product standards or GB/T2975 regulations. Sample processing and preparation: According to the type and depth of notches, it can be divided into: V-shaped notches with a depth of 2mm, U-shaped notches with a depth of 2mm, and U-shaped notches with a depth of 5mm. The standard stipulates the size and tolerances of three standard Charpy impact samples. In the impact sample, the shape and size of the notch have a significant impact on the impact test results. The types of notches or depths of notches are different, and the tendency of embrittlement due to different stress states is different, among which the influence of the radius of curvature and the depth of notches on the experimental results tendency to be different.

Impact testing machineFactors related to the material itself:

The chemical composition, metallographic structure, grain size of the material itself, and whether there are metallurgical defects such as cracks, slag inclusions, segregation, white dots and non-metallic inclusions exceeding the standard, or defects generated during heat treatment all affect the performance of the sample manufacturer. This is where the impact test machine is widely used, which also makes the impact test results more dispersible. Therefore, testers can judge the accuracy of the test results through understanding and analysis of material properties.

In view of the factors that affect the accuracy of the Shopy impact test results, several main factors such as the material itself, the cutting and preparation of the sample, the shape and size analysis of the sample, the requirements for the impact test machine, and the temperature control are briefly discussed. Only through the standardization of the test methods can various factors affecting the results of the Champagne impact test be limited, and the test results are also accurate and comparable.

MoreImpact testing machineInformation: All in Jinan Hengsi Shanda Instrument Co., Ltd.

Tags: Testing machine, universal testing machine, hydraulic universal testing machine, tensile testing machine, impact testing machine, material torsion testing machineRecommended productsPRODUCTS