Company News

Application of hydraulic universal testing machine in mold production

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Application of hydraulic universal testing machine in mold production

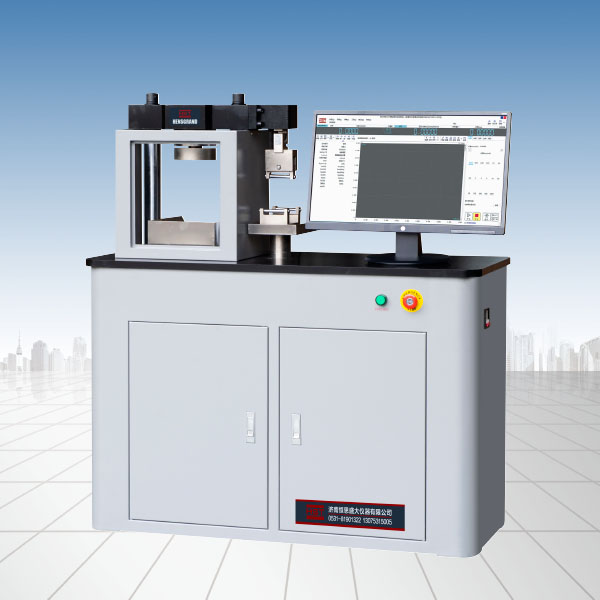

Jinan Hengsi Shanda Instrument Co., Ltd. specializes in productionHydraulic universal testing machineAnd electronic universal testing machine, the following is the application of universal testing machine by our company's technicians in mold manufacturing.

In order to solve the problems of low surface hardness and not wear resistance of molds made of arc sprayed zinc-aluminum alloy, it is necessary to plating the surface of zinc-aluminum alloy, that is, to prepare copper plating on the surface of the mold by electroplating. The pores and inclusions of zinc-aluminum alloy coating and copper plating were observed through scanning electron microscope, and the microhardness of zinc-aluminum alloy spray coating and copper plating were tested, and the combined strength of the spray coating and electroplating were tested. go throughUniversal testing machineThe results show that by plating the surface of zinc-aluminum alloy mold, the surface defects of the mold are eliminated, and the hardness, surface strength, surface finish and corrosion resistance of the mold are greatly improved.

Since electroplating needs to be performed on the conductive prototype surface, it is necessary to coat the surface of the polyvinyl chloride prototype with a layer of conductive copper oil, and then electroplating reaches the required mold working thickness. In order to analyze the performance of the coating, the resulting mold was cut into small pieces, pre-grinded and polished, and the cross-sectional morphology of the spray coating and copper coating were observed using an electronic scanning microscope developed by the company, and the microhardness was measured using a number display microhardness meter.

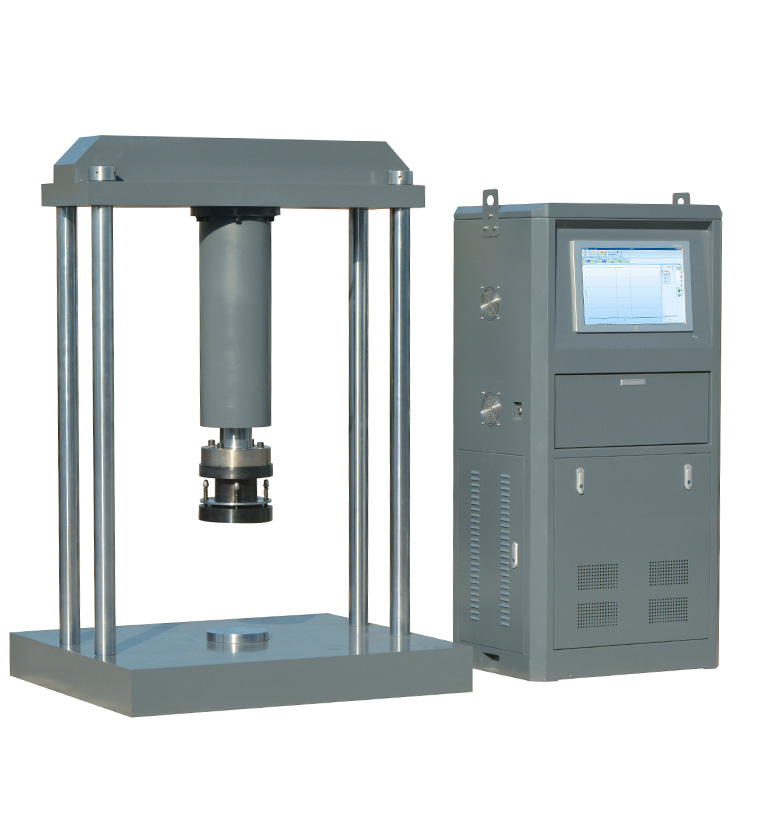

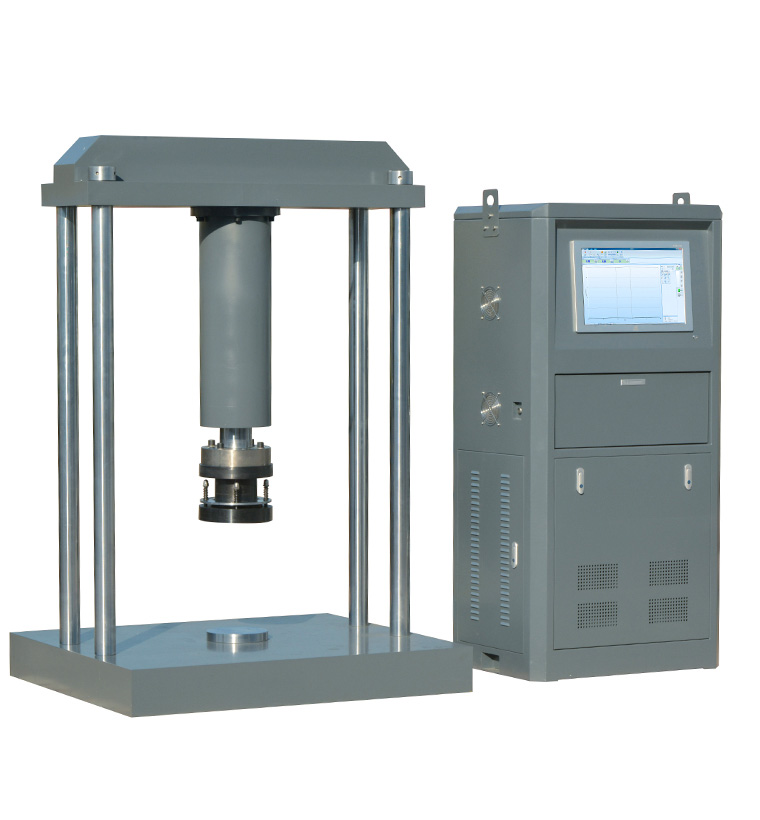

During the entire process, the copper plating forms the cavity surface of the mold, and the arc spraying layer acts as a reinforcement of the backing on the copper plating. In the scheme, the copper plating and spray coating are tested for the bond strength, and the spray material is determined by spraying aluminum wire, zinc-aluminum pseudo-alloy wire and zinc-aluminum alloy wire on the copper plating. The tensile experiment of copper coating and spray coating was performed on a domestic electronic universal testing machine to determine the bond strength of the two.

MoreHydraulic universal testing machineAll information is available on Jinan Hengsi Shanda Instrument Network

Tag: Testing Machine, universal testing machine, hydraulic universal testing machine, tensile testing machine, impact tester, Material Torsion Test Machine

Recommended productsPRODUCTS