Industry Information

A brief analysis of the reasonable operation and adjustment methods of the electro-hydraulic control system of the hydraulic universal test machine

Release time:2021-03-08 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The gain of the same hydraulic universal testing machine is also different in different control states and different test pieces. In addition, the relevant parameters must be adjusted according to its accuracy and width requirements. Therefore, the operator must constantly adjust the relevant parameters according to the test requirements to achieve excellent performance. Below we briefly introduce the reasonable operation and adjustment methods of the electro-hydraulic control system of the hydraulic universal testing machine as follows:

1. When powering on, the console should be powered on first, and then the hydraulic source should be started. If the hydraulic source is started first and the console is not in the control state;

On the one hand, due to the zero position bias of the servo valve, hydraulic oil is inserted into the hydraulic rainbow, causing the piston to move in one direction until it touches the cylinder head, and sometimes even a cylinder crash occurs;

On the other hand, some electronic devices need to be heated up, especially the circuit of the strain gauge, which requires preheating for more than half an hour to make the zero position relatively stable.

Therefore, when powering on, you should first turn on the console to check whether all instruments are in normal conditions.Qinghai Cancer HospitalFor test machines with several control states such as position, force and deformation control, the control state should be placed at the position control point first, and then switched to the corresponding control state as needed after all the power is started.

2. Use a square horizontal instrument to lean on the working platform, align the plumb slature of the oil cylinder, adjust or increase or decrease the horns under its base, so that the error must not be greater than 0.10/1000.

After the accuracy of the hydraulic universal test machine is found, use cement slurry to fill all the gaps under the base to keep the base well combined with the cement foundation, and prevent the test machine from being level due to vibration during use. After the anchor nut is solidified, the anchor nut and the starting test machine are not allowed to be tightened before the cement is dry (the cement drying time is generally not less than 10-15 days).

After the cement is completely dry, tighten the anchor nuts and review the installation accuracy of the test machine to see if it is consistent with the correcting accuracy. If it does not match, it should be corrected again. During the use of the test machine, since the vibration during the test is prone to loosening, the relevant parts should be tightened after the hydraulic universal testing machine is used for a period of time.

To sum up, I have compiled the relevant content of "Reasonable Operation and Adjustment Methods of the Electro-hydraulic Control System of Hydraulic Universal Testing Machine". I hope it can be helpful to you, and I can also communicate directly with our website's customer service. We will serve you wholeheartedly.

- Previous article:Common faults of pressure test machines and their causes

- Next article:How to use a universal test machine

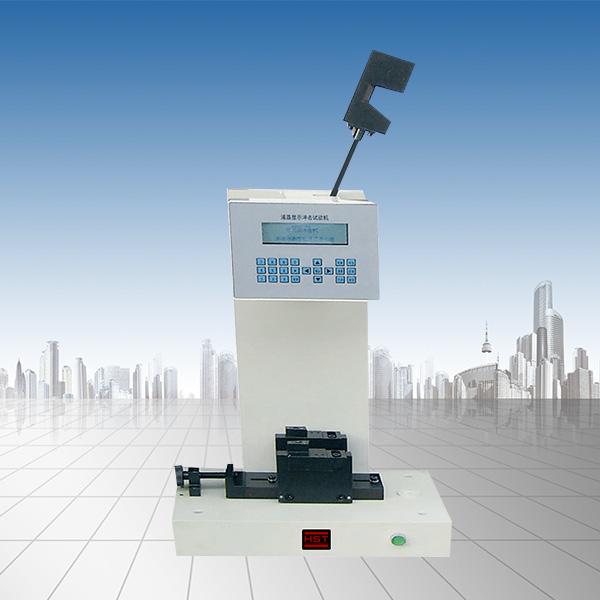

Recommended productsPRODUCTS