Industry Information

What is a test machine

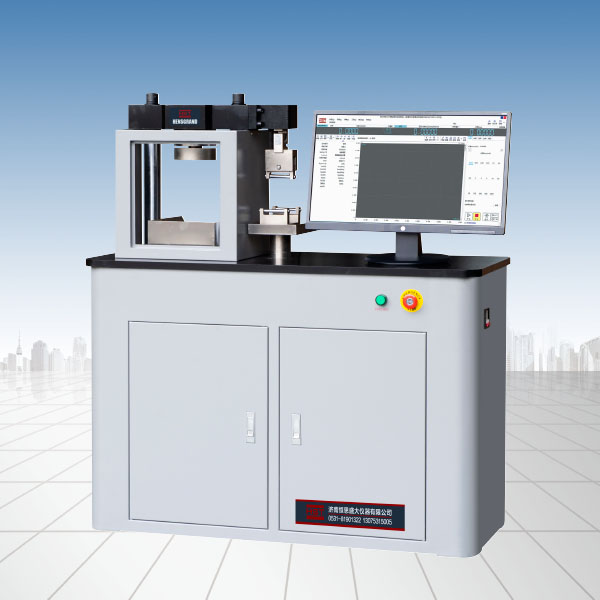

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Testing machineIt is an instrument, system or device that tests and detects the strength, stiffness, hardness, elasticity, plasticity, toughness, ductility and surface and internal defects of materials (metallic materials, non-metallic materials), components, components and structures. Most test machines are technology-intensive high-tech products that integrate machine photoelectric and hydraulics, and most of them are metrological instruments. Test machines are widely used in the field and laboratories of industrial and mining enterprises, metrology and schools. Their application fields involve machinery, metallurgy, construction, aviation, aerospace, military industry, transportation, transportation, quality inspection, metrology, education, medical care and other industries.

1. What is a test machine

The test machine we usually see should actually be called a material test machine, which is an instrument used to test the mechanical and physical properties of various material-type components.

two,Material testing machineClassification

There are many classification methods for material testing machines, and the common ones are:

a) According to the type of output source, there are mainly motor, hydraulic, pneumatic, electromagnetic, etc.;

b) According to the type of indicators at the end of the measurement, there are mainly digital displays and pointers;

c) The main relationships according to the load and time of the sample are: static and fatigue machines.

d) According to the control method, it mainly includes open loop control (manual control) and closed loop control (automatic control)

For closed-loop control, the types of control are: speed control, load control, deformation control, and position control.

e) According to the purpose, it mainly includes general-purpose machines (universal machines) and special-purpose machines.

There are many types of special machines, such as cement press, red brick press, line bending fatigue machine, soft worry machine, electric porcelain bending and twisting machine, horizontal pulling, etc., far balance machine, far three-axis, vibration table.

f) Testing method and test machine

Generally speaking, there are only two types of test machines: the direction of movement (or the direction of force), the type is pulling, the other is pressure, which we usually see pulling, pressing, bending, shearing, peeling, tearing, penetrating, wear, etc., for the sample.

III. Detection and control

Detection and control are two different concepts, but they are inseparable. Generally speaking, for a specific system, under a specific test condition, it only controls a specific parameter, such as the electric pull of our company, which only controls the movement speed of the test bench, and generally there are more than one detection amount. For example, electric pulling, there are loads, displacements, deformations and other detection links.

4. Open-loop control and closed-loop control

Open loop control

Closed-loop control

5. Testing and controlling grading

Testing and grading: It can be divided into improved measurement sensitivity and solve the problem of large management stations calling small objects.

Control binning: used to solve the problem of precise "positioning" and also solve the problem of measurement accuracy.

6. The relationship between gear amplification and range grading

These are two different concepts, but they are related to each other.

Crop amplification refers to a local parameter of the sensor amplifier, while range tracing refers to a counterpart characteristic parameter of the test machine.

The latter has a practical meaning to users, while the former does not require user attention.

- Previous article:How to choose the right tensile testing machine

- Next article:Chinese instrument market share in foreign markets continues to expand

Recommended productsPRODUCTS