News

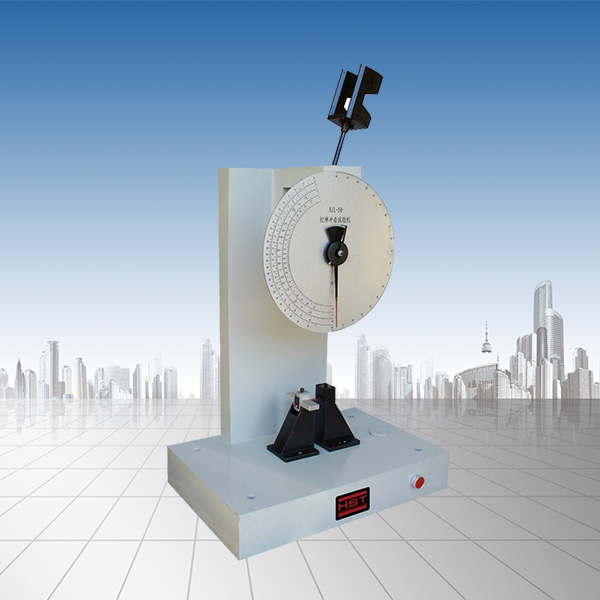

What is the maintenance of the impact test machine?

Release time:2022-11-30 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

The impact tester is an impact test on metal materials. The tests are mainly conducted on ferrous metals with high impact toughness, especially steel and their alloys. So how should the impact testing machine be maintained?

1. All copper pipes must be inspected once a year for leakage.

2. The ground around the fuselage and at the bottom should be kept clean at all times and maintained regularly.

3. When using it, you should always pay attention to whether the jaw support, pendulum, etc. are securely tightened.

4. When the hanger mechanism has not been hung on the hanger mechanism during the swaying process, the staff shall not move or work within the swing range of the pendulum.

5. Apply anti-rust oil to accessories that are prone to rust or auxiliary equipment that are not used for a long time, such as fixtures, jaws, connecting pins, etc.

6. Pay attention to keeping the jaws or relatively sliding surfaces of the fixture clean to avoid bumps.

7. Pay special attention to waterproofing and moisture-proofing. Anti-rust oil should be applied to the middle beam and workbench to prevent rust.

- Previous article:Standard impact test method for metal material notch specimens

- Next article:Electronic tensile testing machine

Recommended productsPRODUCTS