News

Technical parameters and operating steps of mechanical tensile testing machine

Release time:2019-08-17 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

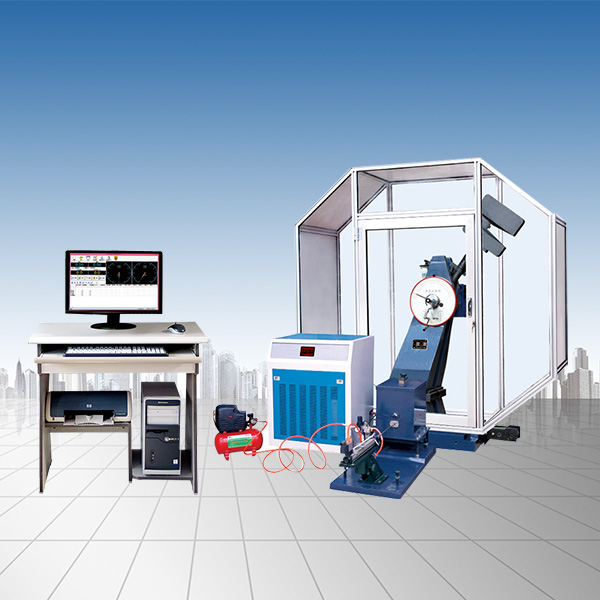

The main machine of the mechanical tensile tester is a door-type structure, which is mainly suitable for tensile tests of rubber, plastic, textile, geotextile, waterproof materials, wires, cables, mesh ropes, metal wires, metal rods, metal plates and other materials. Adding accessories can be used for bending, tearing, peeling and other tests. This time, the editor will share with you the technical parameters and operating steps of the mechanical tensile tester for your reference

1. Technical parameters of mechanical tensile testing machine

1. Test machine accuracy level: Level 1

2. Test force measurement range: 2%~100%FS

3. Relative error of test force display value: ±1%

4. Test force resolution: 1/200000 of the maximum test force

5. Displacement measurement error: ±1%

2. Operation steps of mechanical tensile testing machine

1. According to the maximum possible tensile strength of the sample, select the appropriate dial and hang the corresponding swing weight.

2. Loosen the fixed hook of the swing rod, press the pawl, and observe whether the pointers of the force scale and the elongation scale are zero. If it is not zero, adjustments should be made, then lower the pawls and buckle the swing rod to pull the hook.

3. Rotate the speed control handle to adjust the loading speed. For quick tensile tests, open the front door on the base and move the triangle belt into another pair of pulley grooves.

4. Fix the upper chuck, put the sample into the upper jaw and clamp it firmly, then hang a pre-added tensioning weight on the lower part of the sample, and clamp it into the lower chuck jaw.

5. Release the swing rod hook and upper chuck brake. Turn the reversing handle 5 forward to lower the lower chuck.

6. After the sample is broken and recorded, reset the pendulum and buckle the swing rod hook.

7. Turn the reversing handle backward to reset the lower chuck. At this time, the solenoid hook should be firmly hung with the extension scale, and then perform the second test.

The above are the technical parameters and operating steps of the mechanical tensile tester. In addition, the maintenance of the tester is very simple. As long as you conduct inspections and clean up after using up the tester each time, it can not only save working time, but also effectively extend the life of the tester. Hope it can help you.

Brand account service provider certificationRecommended productsPRODUCTS