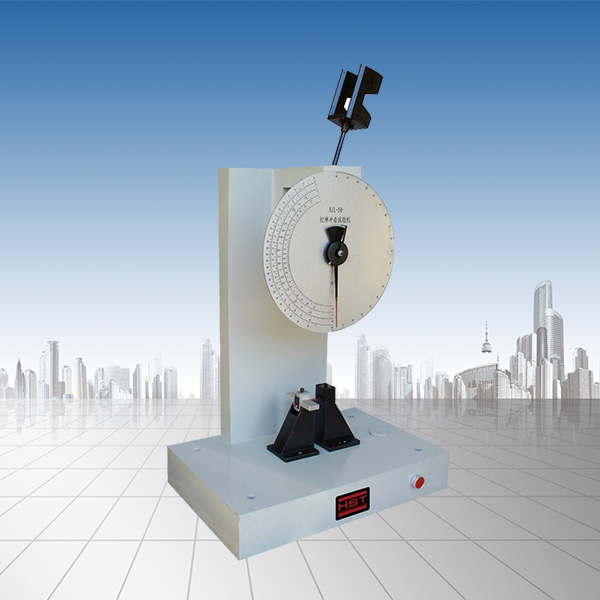

Non-metal tensile testing machines are mainly used for tensile testing machines for non-metallic materials such as leather, rubber, plastic paper, etc. The tensile testing machine must be mandatory for verification in accordance with relevant national regulations. The calibration includes the first calibration and the subsequent calibration. The first verification is generally a third-party verification by the measurement department of the testing machine manufacturer. The test machine must undergo subsequent verification one year after it leaves the factory, and all the measurement departments of the user will verify it. In addition to periodic verification, subsequent verification also includes repair verification. It should be noted that if the tension test machine is transported to the user for a long distance, a comprehensive verification should be conducted after reinstallation. After the verification is passed, the calibration agency of the measurement department will issue a verification certificate. If the verification fails, the verification failure notice will be issued. So what are the influencing factors in the calibration of the non-metal tensile testing machine? Let’s take a look together.

![Factors influencing the verification of non-metal tensile testing machine [Information]](http://www.hssdtest.com/uploads/image/20250418/72/bb6be29c52164ae309cebc3197254f8d.jpg)

Factors influencing the verification of non-metal tensile testing machine:

1. Coaxiality

Non-metal tensile testing machine is subject to design, manufacturing, installation and use. Coaxial error is inevitable. The coaxial error leads to the introduction of additional bending moments during material experiments, which will inevitably affect the test results. There are two methods for identifying coaxiality error: extensometer measurement method and geometric measurement method. Someone has studied the relationship between the two and found that the results measured by the two methods are not the same, and the differences are relatively large.

2. Range and display error

Some non-metal tensile test opportunities that are frequently used have excessive errors in the display value within certain ranges. The more common one is the error in the maximum range. The reason is the specific habits of the user, such as shifting gears or replacing a larger test machine after approaching the maximum range. As a result, the maximum range is almost not used. Compared with the commonly used range, the friction force in this section will also cause the measurement to be smaller. Therefore, in this case, you should test more times at a large number of routes, and then check to eliminate this effect.

3. Extension meter

In addition to the host, the extensometer will also affect the detection results. In addition to the first verification, if you need to check, you should check it in the cycle verification, and some users often ignore this.

The above are the factors influencing the verification of non-metal tensile testing machines. I hope the above brief introduction can help you. If you want to know more detailed information about the testing machines, you are welcome to follow our company in Shandong. This not only provides you with high-quality testing machines, but also provides various equipment information to help you further understand the equipment. If you have any needs, please come and consult.

![Factors influencing the verification of non-metal tensile testing machine [Information]](http://www.hssdtest.com/uploads/image/20250418/72/bb6be29c52164ae309cebc3197254f8d.jpg)