News

Analysis of requirements and maintenance of hot and cold impact test chambers

Release time:2019-09-20 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

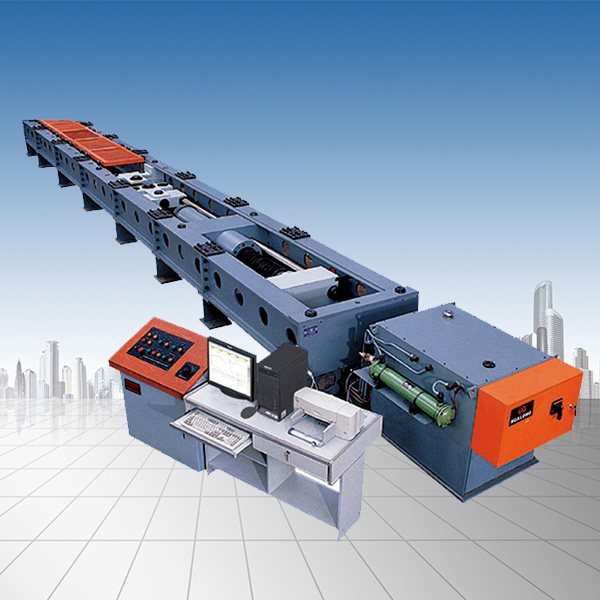

The hot and cold impact test chamber is designed and manufactured according to user requirements and is suitable for high and low temperature impact tests of complete machines and parts of aviation, aerospace, military, ships, electricians, electronics and other products, as well as storage and testing in high or low temperature environments. It allows users to conduct corresponding climate and environmental acceleration tests on the entire machine (or components), electrical appliances, instruments, materials, coatings, plating, etc. in order to evaluate the test products or test products. Let’s introduce the requirements analysis and maintenance of hot and cold impact test chambers.

1. Analysis of the requirements of hot and cold impact test chambers

With the gradual increase in demand for environmental testing equipment in industries such as electricity, communications, coal mines, aviation, quality inspection, scientific research, and universities, my country's hot and cold impact testing machines meet the development of various industries in terms of quantity and quality, and have driven the development of instrumentation and machinery industries. In response to this phenomenon, industry insiders have made the following analysis of the hot and cold impact testing machine industry: First, it is everyone's change in demand: on the one hand, energy conservation and consumption reduction, emission reduction and a low-carbon economy have become China's national policy, and a number of new types of properties are presented. The 21st century is the industrial era of economic outbreak, and more and more products are moved into laboratories.

Then there is the change in competition among manufacturers in the industry: the globalization of the world economy has led to more fierce competition in the domestic market, and the Chinese market has become a hot spot for global attention. Famous foreign hot and cold shock test machine companies have increased their sales efforts, and the investment methods have gone from simple sales to OEM, from sole proprietorship to establishing R&D, localization has deepened from time to time, strengthening competitiveness, and the competitive advantages of domestic companies are gradually eliminating.

And there is also the transformation of skills. In recent years, hot and cold impact test chambers have begun to develop from a more mature data state to a common sense state, making it more applicable to enterprises. Smart instruments that are currently commonly used in the field of industrial automation will usher in a lot of room for development.

At present, the demand market of the hot and cold impact testing machine industry is quietly changing. In addition to bringing a lot of sales to the environmental testing equipment industry, these situations have also proposed new challenges. The environmental testing industry must not only maintain a steady momentum, but also adapt to new development trends. Only by developing and launching new products from time to time can we achieve faster development.

2. Maintenance of hot and cold impact test chamber

1. In order to extend the service life of the hot and cold impact test chamber, it is necessary to strengthen the daily maintenance of the equipment to ensure that it can effectively reduce mechanical wear during normal operation and ensure that the mechanical equipment can work in the environment it adapts to;

2. Regular maintenance of the equipment should be carried out, and every part should be handled correctly during the maintenance process;

3. The duty team must strongly require the maintenance of all types of machinery according to the mechanical maintenance procedures and maintenance categories, and shall not delay without reason. In special circumstances, maintenance must be postponed after approval by the specialist in charge;

4. The maintenance machinery of hot and cold impact test chambers must ensure quality and proceed item by item according to the prescribed items and requirements. No insurance shall be missed or lost. Problems found during maintenance projects, maintenance quality and maintenance should be recorded and reported to the specialist in this department;

5. Maintenance personnel and maintenance departments should achieve "three inspections and one handover (self-inspection, mutual inspection, full-time inspection and one handover qualification)", constantly summarize maintenance experience, and improve maintenance quality.

Mechanical equipment is essentially the same. Only by mastering the correct method can the entire experimental process be smoother and the experimental data are more accurate. The above is an introduction to the requirements analysis of hot and cold impact test chambers and maintenance matters. I hope it can help you.

Recommended productsPRODUCTS