News

Operation precautions and installation methods of universal testing machine

Release time:2019-11-13 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

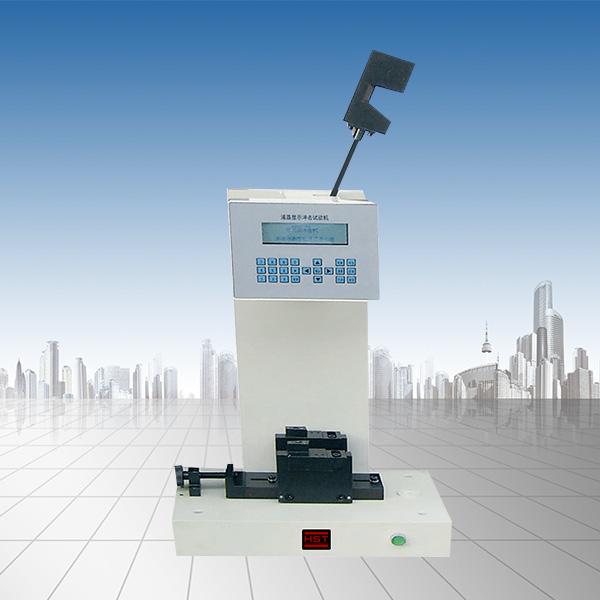

The universal testing machine is a mechanical testing machine that can perform various tests such as tensile, compression, bending and torsion. Common ones include lever pendulum type and hydraulic pendulum type. They are mainly used for mechanical properties tests of metal and non-metallic materials. They are ideal testing equipment for industrial and mining enterprises, scientific research institutions, colleges and universities, engineering quality supervision stations and other departments. Next, our company's technicians will introduce to you the operating precautions and installation methods of universal testing machines. Let's learn about it together.

1. Precautions for operating a universal test machine

1 During the test, if the oil pump suddenly stops working, the load applied should be removed to reduce the pressure of the oil pump, and then restart the pump after inspection. Do not start the oil pump under high pressure.

2 During the test, if the electrical appliance fails and the start or stop button does not work, the power supply should be cut off immediately to stop the test machine.

3 To prevent the specimen from flying out when it breaks and causing accidents, you can make your own protective plate.

4 When using, pay attention to whether the pressing plate bolts on both sides of the upper and lower jaw seat wedge blocks are loose. It should be tightened at any time to prevent the blocks from flying out and causing accidents.

5 Before driving, tighten the oil supply valve to prevent the piston from rising suddenly and rapidly.

6 The cross beam lifting is used to adjust the test space. If the test block is incorrectly operated and the test block is pressed by mistake, it will cause the chain buckle in the driving mechanism, and the moving cross beam is stuck, etc.

7 When installing the test machine, connect the three-phase power cord correctly, and the cross-sectional area of the neutral wire shall not be less than 1.5 square mm. Firmly connect the ground wire and connect the connection between the host and the screen display part.

8 Pay attention to the direction of the motor rotation during the first test run. If the direction is opposite, replace any two-phase power cord position.

9 Check whether the limit switch is flexible and reliable, whether the thermal relay current setting value is appropriate, and the specifications must be the same when replacing the fuse.

2. Installation of universal testing machine

The universal testing machine uses hydraulic pressure to apply test force, and the test data is accurate and reliable. In order to ensure the high accuracy of the test force reading of the test machine, this machine uses an oil pressure sensor to measure the force. After amplification, the screen displays the test force, force peak value, and loading rate. The oil source is located at the lower part of the control cabinet and is equipped with a dual flow transformer plunger pump, which is driven and operated by the motor. The hydraulic system is mainly controlled manually, which is more convenient to operate, safe and reliable. It is mainly used for tensile, compression, bending, shearing tests of metals and non-metals. It can be widely used in building materials, metallurgy, scientific research units, colleges and universities, quality testing centers and commodity inspection departments. It is an ideal testing machine for the industry requirements of production, scientific research and teaching.

Its design basis is standard: GB/T3159-2008 "Hydraulic Universal Testing Machine".

To sum up, it is a related introduction to the operation precautions and installation methods of the universal testing machine. We should pay attention to the problems found during use of the testing machine and promptly eliminate them to avoid errors in your test results. It is to regularly check and correct the test machine to ensure the normal use of the test machine. If you have any unclear areas, please call us for consultation.

Recommended productsPRODUCTS