News

Calibration of universal testing machine sensor

Release time:2022-07-20 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Taking a sensor with a range of 50kN as an example, the calibration operations of other sensors with a range of similarity.

1. Calibration of gear (range):

①. Select the gear (range):

②. Clear the display value: Clear the zero when the force sensor is not subjected to force.

③. Select a calibration point of 10.000kN: just click on the line with the mouse. (The calibration points should be selected from small to large for calibration)

Apply force to the sensor and use a standard dynamometer to measure the current force under the sensor;

When the standard dynamometer shows that the current sensor's force is 10.000kN, click the calibration button immediately.

④. Select the second calibration point: just click on the line with the mouse.

Apply force to the sensor. When the standard dynamometer shows that the current sensor force is 20.000kN, click the calibration button immediately.

⑤. Click the calibration points 30, 40, and 50 in turn, and follow the above steps to calibrate the range (gas).

2. Calibration of the second gear (25kN range):

①. Select the second gear (25kN range):

②. Clear the display value:

③. Introduction to calibration methods for each calibration point in the same level.

3. Calibration of other gears (range):

The same method.

two. Calibration of extensometer

Take an extensometer with model 25/50 as an example: the range of this extensometer is 25mm and the gauge is 50mm.

The calibration operations of other extensometers of ranges are similar.

1. Calibration of gear (range):

①. Select the gear (range):

②. Clear the indication value: It should be cleared when the distance between the extensometer cutting edge (chuck) is the gauge distance.

The positions of the two cutting edges can be fixed with an extensometer gauge (or caliper).

③. Select a calibration point of 25.0mm: just click on the line with the mouse. (Calibration points should be selected in the order from small to large for calibration)

Increase the distance between the blade edges by 25mm, that is, adjust it to 75mm;

④. Click other calibration points in turn and follow the above steps to calibrate the range (gas).

2. Calibration of other gears (range):

Calibration method is the same as the calibration method (25mm range).

- Previous article:Introduction to technical problems of material tensile testing machine

- Next article:Several categories of tension machine sensors

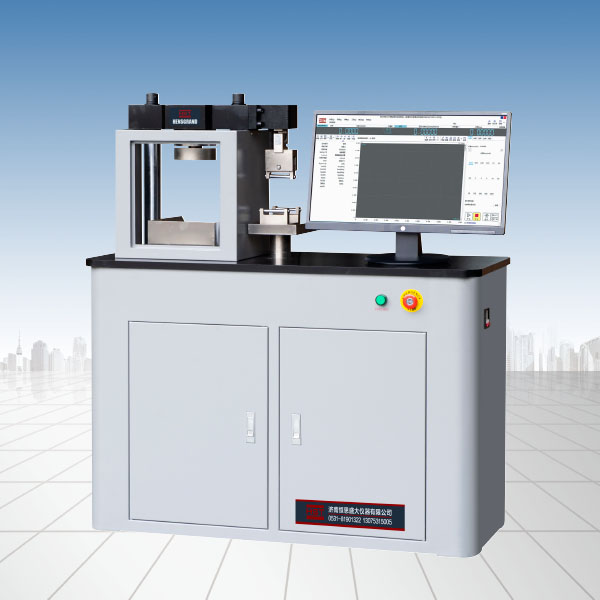

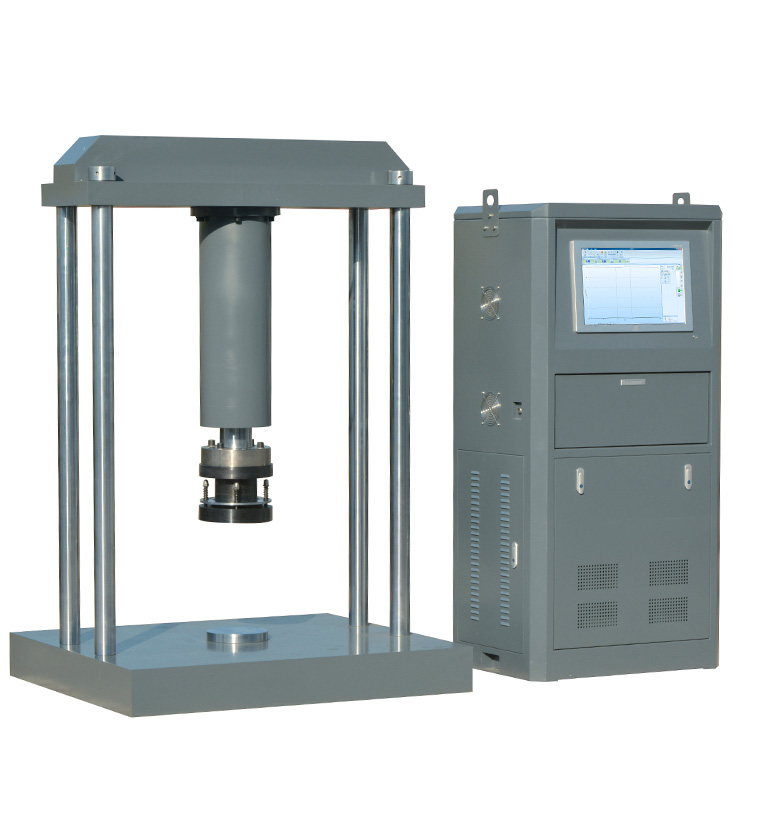

Recommended productsPRODUCTS