News

What are the safety and service life of the woven bag tensile tester?

Release time:2022-07-20 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

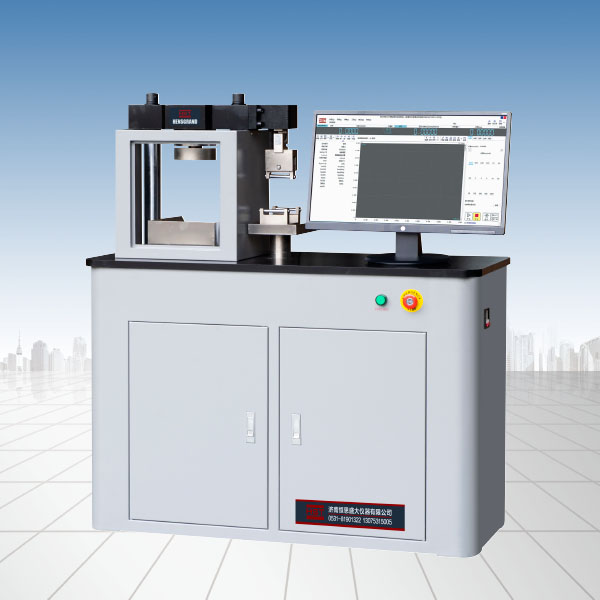

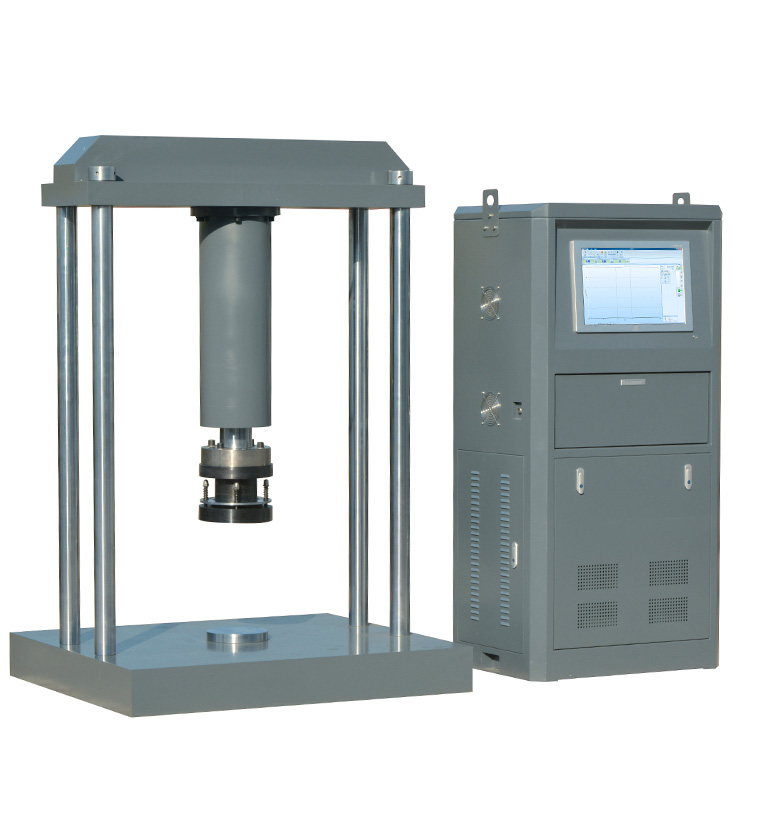

The main unit of the braided bag tensile tester is a door-type layout, which is mainly suitable for tensile tests of rubber, plastic, textile, geotextile, waterproof data, wires, cables, mesh ropes, wires, metal rods, metal plates and other data. Adding accessories can be used for bending, tearing, peeling, etc. It is widely used in the inspection and analysis of data in factories and mining enterprises, hardware and building materials, aerospace, machine manufacturing, wires and cables, rubber and plastics, textiles, home appliances, papermaking and other industries. It is an ambition testing equipment for scientific research institutes, major colleges, industrial and mining enterprises, technical supervision, commodity inspection and arbitration and other departments. So, what are the safety precautions for placing a bag tensile tester and what are the precautions for extending the service life of the equipment?

1. Some safety precautions for placing a woven bag tensile tester

1. The key parts of the equipment (such as jaws, gearboxes, etc.) need to be frequently filled with lubricating grease.

2. The computer should be placed in a dry and ventilated room.

3. If not used for a long time, power must be turned on once a month.

2. Things to note when extending the service life of the woven bag tensile tester

1. It is strictly forbidden to use machines with overload and overspeed regulations.

2. It is strictly forbidden to collide with the lifting screw and lubricating oil is applied on time.

3. When changing the triangle belt in a machine-type woven bag tension tester, pay attention to the position of the hand to prevent clamping the fingers. The transmission part must be covered with a protective cover.

4. When the electronic speed control type adjusts the lifting speed, it does not cause too fast operation.

5. Before using the 50KN tensioner, pay attention to the tightening environment of the clamp lifting screws.

6. When lifting and dialing the fixtures up and down, the woven bag tensile tester must be stable. It can avoid collisions and often reflect on the tightening environment of the fixture screws.

7. When changing the test fixture, pay attention to common ground to prevent damage.

8. When opening the fixture to pick up the sample, pay attention to the clipping distance of the sample, as there will be too much or too little.

9. When connecting the woven bag tensile tester and microcomputer, it must operate according to the requirements of the law model. It is strictly forbidden to cause disorder of the law model model;

10. Before printing, reflect whether the printer has paper and make up for it in real time.

11. After the operation of the woven bag tensile tester is completed, the machine should be turned off according to the specifications and the universal tensile tester is strictly prohibited from directly blocking the power supply.

12. Strictly implement the annual inspection system and the national metrology and appraisal agency shall conduct parameter identification and certification on time.

Recommended productsPRODUCTS