News

Test machine repair, test machine failure

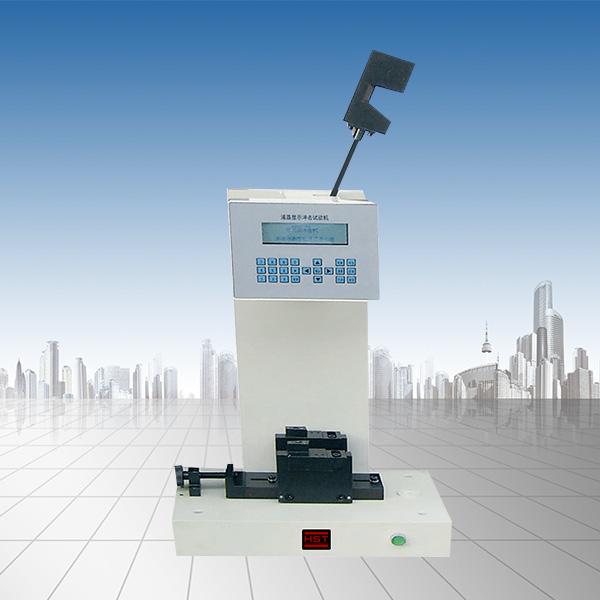

Release time:2025-03-14 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Testing machineSome problems will inevitably arise during use, some problems are obvious, such as: not stopping after breaking, not showing force values, etc., but some problems are relatively hidden, and may only be distinguished by the manufacturer, and the test results caused by these problems are the most inaccurate. Some points for the maintenance of the test machine and the failure of the test machine are for reference:

Device Problems:

1. Test machine force sensor: The sensor will inevitably be damaged during use, but it may not be able to show that it has been damaged. Although the results are inaccurate, 10% or 20% of the maximum load of the general metrological verification equipment is the starting point of the verification. Some inferior sensors have a considerable error of less than 10%.

2. Installation position of displacement sensor: Due to design differences, the installation positions of displacement sensors are different: but the ones installed on the screw will be more accurate than those installed on the motor;

Structural issues:

1. The beam of the test machine is too thin: especially when conducting large tonnage metal tests, because the beam is also subjected to stress at the same time, it will cause deformation, which will also affect the test results. Therefore, it is better to choose good cast steel materials. If it is cast iron materials, sometimes they will even be overwhelmed and directly break;

2. Installation accuracy: Equipment that has not undergone strict inspection or equipment that has no detection strength is prone to such problems, and it is also an invisible killer that affects detection accuracy;

3. Control test speed unstable: speed unstable may occur due to various reasons, such as the influence of synchronous belts or reducers. If the equipment is violently assembled during the production process, it will accelerate the aging life of these two parts. If it is not replaced in time, it will affect the results of the experiment.Testing machineSpeed affects the experimental results, so speed verification and verification are required;

4. Problems with fixtures: After long-term use, the fixture jaws will be worn, the teeth will be deformed, resulting in unreliable clamping, or causing damage to the sample, affecting the final test results;

5. The safety protection device has a failure: The safety device may have problems because it is often not used, because it needs to be tested frequently just in case.

- Previous article:Wire and cable tension testing machine

- Next article:Preparation of tensile test specimens of glass fiber woven fabric

Recommended productsPRODUCTS