Company News

What are the working principles of the electronic universal testing machine and the hydraulic universal testing machine?

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1.Electronic universal testing machineIt is widely used in various metals, non-metals, composite materials, medicine, food, wood, copper, aluminum, plastic profiles, wires, cables, paper, films, rubber, textiles, aerospace and other industries to conduct testing of tensioning and other functional targets. Various experimental data processing software and experimental auxiliary tools can also be customized according to domestic and international standards provided by users.

Generally speaking, the test working principle of the electronic universal testing machine is:

The sample is clamped between the two chucks of the clamp, and the two chucks move relative to each other. Through the force value sensor located on the moving chuck and the machine's built-in displacement sensor, the force value and displacement changes during the test are collected, thereby calculating performance indicators such as tensile, tear, and deformation rate of the sample.

The electronic universal testing machine is suitable for users who only seek related data such as force value, tensile strength, compressive strength, etc. If you need to take more complex parameters, a microcomputer-controlled electronic universal material testing machine is your better choice. In terms of cost-effectiveness, electronic universal material testing machines with a temperature of less than 30 tons have more advantages.

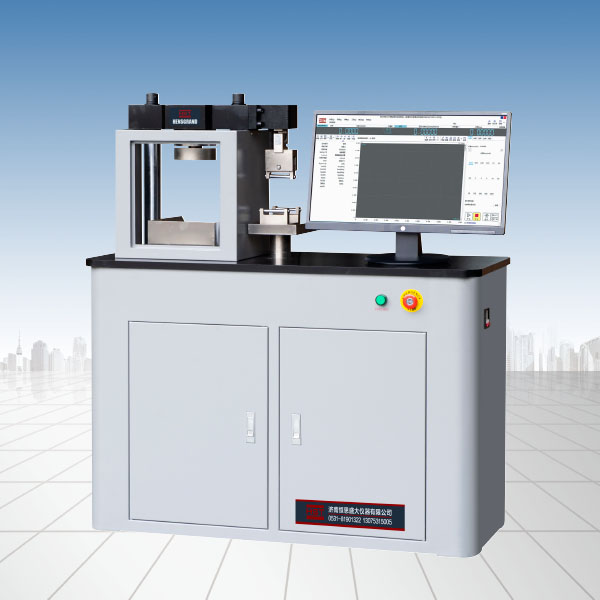

2. The hydraulic universal material testing machine is mainly used for mechanical functions such as stretching, tightening, bending of metal and non-metal materials and parts, components, and components. It is an ideal experimental equipment for industrial and mining enterprises, construction materials, quality inspection intermediates, water conservancy and hydropower, bridge engineering, scientific research institutes, and mechanics laboratories of colleges and universities.

Generally speakingHydraulic universal testing machineThe test works:

The high-pressure oil pump supplies oil to the working oil cylinder, and through the piston movement, the platen and upper beam (upper jaw seat) are pushed upward to perform the tensile or compression test of the sample. The tensile test is performed between the upper beam and the moving beam of the main machine, and the compression test is performed between the platen of the main machine and the moving beam of the main machine. The adjustment of the test space is achieved by driving the double screws to rotate simultaneously by driving the driving mechanism (lifting motor, sprocket, chain, etc.).

Manually adjusted hydraulic universal testing machine is cheap and suitable for product inspection and single data target testing of industrial and mining enterprises. The hydraulic servo universal material testing machine is suitable for steel, building materials, and testing laboratories with high requirements.http://www.hssdtest.com/

Recommended productsPRODUCTS