Company News

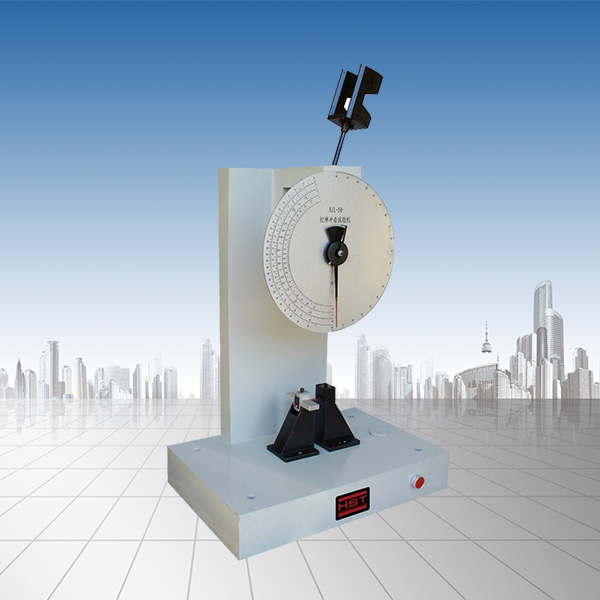

Understand the impact test machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Impact testing machineIt is a new impact testing machine that can instantly measure and record the characteristic curves of materials during impact. By replacing the pendulum and the sample base, two types of tests can be achieved: simple support beam and cantilever beam can be achieved. It detects angular displacement signals and sends them to the computer for data processing, with high accuracy. The test for determining the impact load resistance of metal materials, also known as the impact toughness test. It is one of the basic test methods for material mechanical properties testing. In the impact test, the work consumed to rush the sample is called impact work, and the unit is Joule (J), expressed in Ak. Dividing Ak by the cross-sectional area F at the sample notch gives Ak/F=ak, which is joules/cm2 (J/cm2), which is called the material impact value. ak can be used to evaluate the toughness and brittleness of materials, but cannot be used directly in design calculations.

According to the sample shape and breaking method,Impact testing machineIt can be divided into three types: bending impact testing machine, torsional impact testing machine and tensile impact testing machine. Among them, the pendulum bending impact test machine is widely used. The results of the impact test of the simple impact sample are closely related to the shape of the sample. The test results obtained with samples of different sizes and shapes cannot be compared with each other. Therefore, all countries stipulate that there are standard samples. In Chinese standards, the application of plum samples and chapy V-shaped notch samples is mainly used. The impact test is very sensitive to the tissue defects of metal materials, and can detect the defects and tissue changes caused by the material during smelting and processing processes. When the same sample is subjected to impact test at a temperature from high to low, the impact work (or impact toughness) will be from large to small, the crystal fracture will be from small to small, and the plastic deformation will be from large to small, which means that the material transitions from a tough state to a brittle state. Usually, the temperature when 50% of the crystal fracture area appears on the fracture is called the toughness-brittle transition temperature or brittle transition temperature.

- Previous article:Summary of conversion of mechanical test units

- Next article:Instructions for use of tensile testing machine

Recommended productsPRODUCTS