Company News

Introduction to the 4-step principle of Hengsi Cup Testing Machine

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

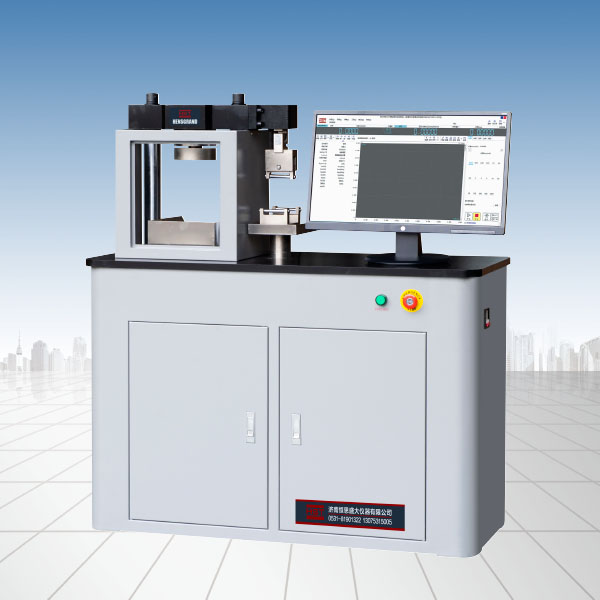

forUniversal testing machine, tensile testing machine, impact testing machine and other instruments and equipment are familiar to customers. The following analysis of the working principle of the cup burst testing machine:

1. The cup protrusion test machine adopts a new structural principle, which is used to load the servo motor at a constant speed, and can realize constant rate control. The stamping process is controlled by a PC computer, and the stamping speed can be adjusted steplessly and pre-adjusted. (In the past, constant rate control could not be achieved by the oil source after the oil cylinder).

2. The force measuring device has been changed from the hydraulic sensor to a spoke sensor in the past, and the cup bump value measurement is measured by an encoder. Combined with the spoke sensor (direct force measurement) greatly improves the accuracy and reliability of the test machine to measure the cup bump value.

3. The clamping force is independently loaded by the hydraulic oil source, the clamping force can be adjusted, the data is displayed synchronously and can be independently calibrated.

4. CupTesting machineThe fixture is easy to replace and the sample is loaded and unloaded. After the sample is placed, the clamping can be completed by pressing the automatic button. The test parameters can be entered and changed. The stamping process is fully automatic and one-click, without human influence. Closed-loop control can be realized. The pulse pressure value drops and automatically stops the sample when there is a crack. At the same time, it is easy to observe the test process, and can more accurately judge the cup bump value at the moment of cracks. The test data computer displays, and has peak memory functions, namely punch pressure, cup burst value, etc., to realize the report, storage, batch, curve drawing of test results, automatic memory of deformation height, and automatically restore to the state to be tested after one test.

Recommended productsPRODUCTS