Company News

Understanding of the packaging machine drop test procedure

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

1.1 Preparation of test samples Prepare test samples according to the requirements of GB/T4857.17.

1.2 Number of each part of the test sample. Number of each part of the test sample according to the demarcation of GB/T4857.1.

1.3 Pretreatment of test samples According to the definition of GB/T4857.2, select a prerequisite for temperature and humidity pretreatment of the test samples.

1.4 Temperature and humidity prerequisites during test The test should be carried out under the same temperature and humidity as pretreatment. If the pretreatment prerequisite is not met, the test should be carried out as close as possible to the pretreatment temperature and humidity.

1.5 Selection of test intensity value Select the test intensity value according to the GB/T4857.18 definition.

1.6 Test steps

Drop the height position and support it in the predetermined state. The difference between the straight height and the predetermined height shall not exceed 5.6.1 of the predetermined height and lift the test sample to the required ±2%. The drop height refers to the interval between the point and the impact table when the test sample is ready to be released.

1.6.2 Release the test sample according to the following predetermined status:

a. When the surface falls, the angle between the falling surface of the test sample and the horizontal surface shall not exceed 2°;

b. When the edge falls, the angle between the falling edge and the horizontal south does not exceed 2°, and the error between the angle between the demarcated surface and the impact table on the test sample is not greater than ±

5° or 10% of the included angle (whichever is larger), so that the gravity line of the test sample passes through the falling edge;

c. When the angle falls, the angle error between the demarcated surface on the test sample and the impact table is not greater than 5 or 10% of this angle (whichever is the larger value), so that the gravity line of the test sample passes through the angle being dropped;

d. No matter what state or appearance the test sample is, the gravity line of the test sample should pass through the surface, line, and point that is being dropped.

1.6.3 The difference between the actual impact speed and the impact speed during free fall shall not exceed ±1% of the time during free fall.

1.6.4 After the test, check the damage of the packaging and interior items according to the relevant standards or demarcations. And analyze the test results.

2 Experimental Lecture

a. Name, specification, model, number, etc. of the interior;

b. Number of test samples;

c. Specific description: name, size, structure and material specifications of the packaging container; accessories, buffer liners, support, fixing methods, sealing, bundling status and other protective measures;

d. The mass of the test sample and the mass of the contents, measured in kilograms;

e. Temperature relative humidity and pretreatment time during pretreatment;

f. Temperature and relative humidity of the test site;

g. Details the placement status of the test samples during the test;

h. The order of falling and the number of falling times of the test sample;

i. The drop height of the test sample, measured in millimeters;

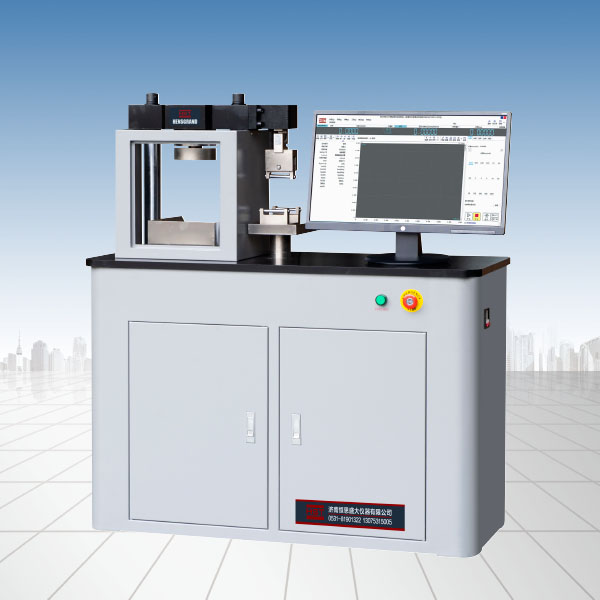

j. Types of equipment used for the test;

k. Recording of test results, and any phenomena observed in the test that helps accurately explain the test results; l. Explain the differences between the test methods used and this scale;

m. Test date, signature of the test staff, and stamped by the test unit.

Recommended productsPRODUCTS