Company News

Introduction to commonly used test methods for tensile experimental machines

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

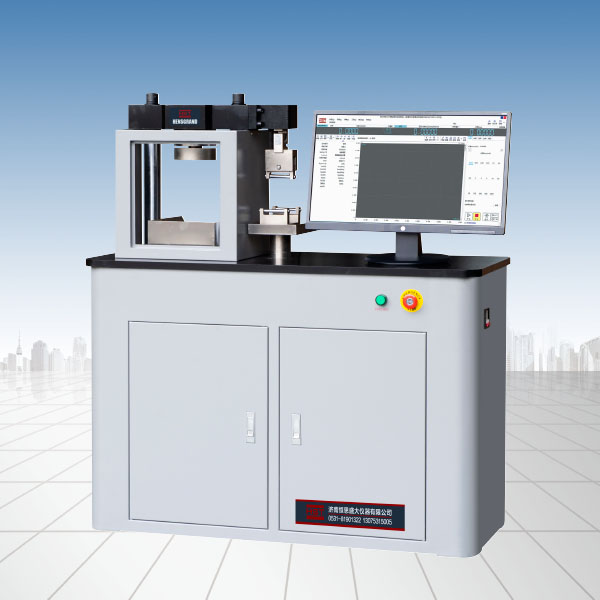

Tension Experimental MachineIntroduction to common test methods

1. Impact experiment

It is to use the energy difference before and after the pendulum impacts the sample to determine the toughness, active brittleness of the sample. The characteristics are large impact force, short effect and fast transformation.

2) (bcd)-Captification deformation stage point c corresponds to PS c-d waveform segment "platform".

3) dB-average plastic deformation stage Point B corresponds to the intensity limit load (acceptable load) of the Pb value data.

4) BK-Part concentrated deformation stage (neck) point K is the fracture load corresponding to the Pk value of the fracture point.

2. Tension experiment, the commonly used instruments are all-round data experimental machines andTension Experimental Machine, the first thing is to slowly apply loads on both ends of the sample, so that the test subject is subjected to axial tension locally, causing the sample to extend in the axial direction, and usually proceed until it is broken. Tensile strength and plastic characteristics of the data can be measured through tensile experiments. The tensile samples must meet the tensile experimental requirements of relevant national and industry standards for divergent data. Tensile experimental curve Stress-strain tensile curve. Shanghai Hengyu Instrument Co., Ltd.'s main products include: tensile machine, tensile test machine, peeling force test machine, vulcanization test machine, vibration test bench, universal material test machine, universal tensile machine, tensile test machine, electronic tensile test machine, electronic tensile machine, rubber tensile test machine, rubber tensile machine. The tensile curve can be divided into four stages: 1. 10ab-elastic deformation stage. The corresponding PP value of point a is called proportional limit load. Point b corresponds to Pe value called elastic limit load (resistance without eternal deformation) 0-Segment a L proportional to p linear stage a-B segment extreme microplastic deformation (0.001-0.005%)

3. Hardness experiment

It is an agile and economical mechanical experiment method, one of the common methods for measuring the mechanical functions of data, and it is a unique experiment that does not damage the mechanical functions of the test piece. There are also changes experiments, creep experiments, slack experiments, and durability experiments in product detection.

4. Closing experiment

However, contrary to tensile experiments, it is used to measure the pressure strength, relative shortening rate and cross-sectional increase rate of data under static pressure. The fundamental requirement for the compaction pattern is that the two support end faces must be parallel to each other. The user usually uses all-around experimental machines and pressure experimental machines. Bending experiments are mainly used to determine the bending strength limit, elastic modulus and deflection in data or components. It can be divided into simple-supported beam bending experiment and pure bending experiment

5. Shear experiment

The first is to measure the shear resistance of data, which is generally used to evaluate the quality of rivets. Shear experiments are divided into single shear and bidirectional shear experiments, and the use of instruments is omnipotentMaterial testing machine.

- Previous article:Principle of drop test of Hengsi packaging

- Next article:Understanding of the packaging machine drop test procedure

Recommended productsPRODUCTS