Company News

How to conduct low temperature tests for impact testing machines

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Impact testing machineIt is divided into high and low temperature testing machines, and tests are carried out with different needs. Our company's technicians have described the low temperature tests conducted by the low temperature impact testing machine in detail.

1. Refrigeration system and compressor of low-temperature impact tester: In order to ensure the cooling rate and temperature requirements of the test chamber, this hot and cold impact test chamber adopts a binary composite Freon refrigeration system composed of imported semi-enclosed compressors. The stacked system includes a high-pressure refrigeration cycle and a low-pressure refrigeration cycle, and the connected container is an evaporation condenser. The function of the evaporation condenser is to use the low-pressure circulating evaporator as a high-pressure circulating condenser.

The design of the refrigeration system uses energy regulation technology. An effective treatment method can not only ensure that the energy consumption and cooling capacity of the refrigeration system can be effectively adjusted under the normal operation of the refrigeration unit, but also reduce the operating costs and faults of the refrigeration system to a relatively economical state.

2. Low temperatureImpact testing machineRefrigeration working principle: Both high and low refrigeration cycles adopt reverse card cycles. This cycle consists of two isothermal processes and two adiabatic processes. The process is as follows: the refrigerant is compressed to a higher pressure through the compressor, which consumes work to increase the exhaust temperature. Then the refrigerant isothermal exchanged with the surrounding medium through the condenser to transfer heat to the surrounding medium. After the refrigerant is insulated and expanded through the shutoff valve to perform work, and the temperature of the refrigerant decreases. This cycle repeats itself to achieve the purpose of cooling down.

3. Cooling method: air-cooled or water-cooled.

4. Refrigerant: Use R404A (low pressure cycle) and R23 (high pressure cycle) environmentally friendly refrigerants produced by DUPONT, the United States.

5. Refrigeration auxiliary parts: The main refrigeration accessories and control devices are imported originals, American SPORLAN thermal expansion valve Italian CASTEI solenoid valve; American RANCO pressure controller, oil pressure controller, American PACKLESS shock absorber hose, European and American AC&R Shantou separator, Italian CASTEL shutoff valve, American SPORLAN filter, etc.

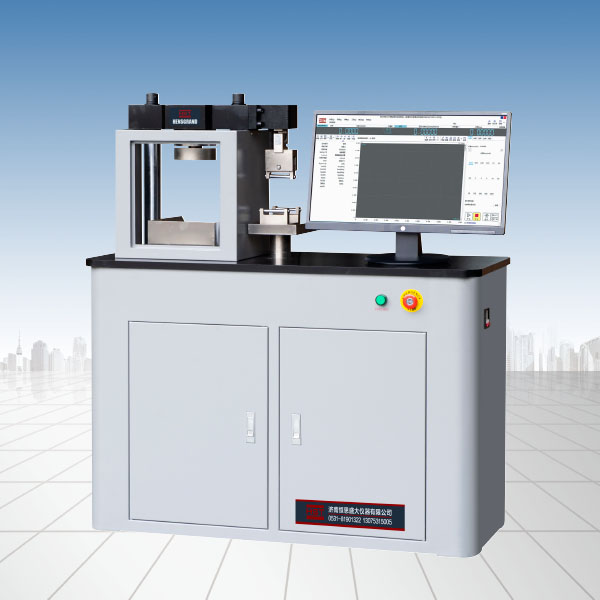

MoreImpact testing machineAll information is in Jinan Hengsi Shanda Instrument Co., Ltd.

Tag: Universal Testing Machine, hydraulic universal testing machine, tensile testing machine, impact tester, twisting test machine, Material Testing Machine

- Previous article:Impact testing equipment--understanding of hydraulic pulling beds

- Next article:Application of tensile testing machine test on shoes

Recommended productsPRODUCTS