News

What elements should be paid attention to when testing materials of optical cable winding test machines

Release time:2019-04-20 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Optical cable winding test machines are often used for winding and torsion tests of wires and cables such as aluminum wires, steel wires, steel rods, steel core aluminum stranded wires, etc. They meet the standard requirements. They require winding and torsion tests for aluminum wires, steel wires, and copper rods. They are a necessary testing tool for steel core aluminum stranded wire manufacturers.

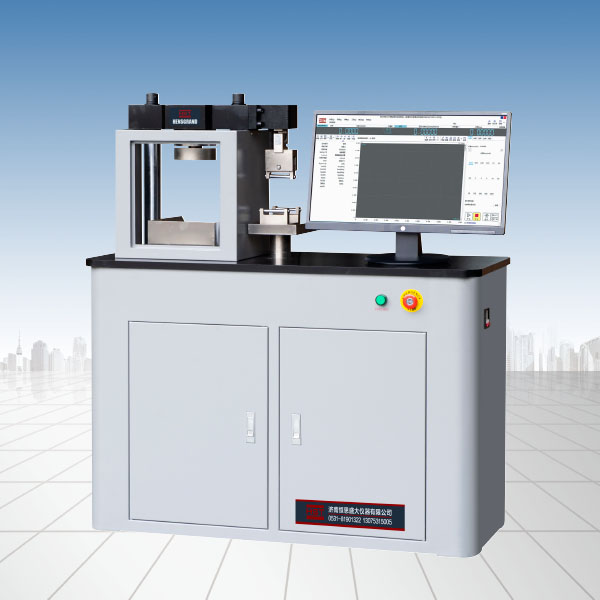

The optical cable winding test machine is composed of an active wheel and a passive wheel. The active wheel runs smoothly and has low noise. The number of windings of non-contact sensors is detected by non-contact sensors, which avoids the disadvantage of easily causing device wear. It has a remote communication port to facilitate remote control of computers. It is a down-mounted hydraulic universal testing machine. It is mainly used for tensile, compression, bending, shearing tests of metal materials and non-metallic materials such as cement, concrete, and plastic. Add accessories to complete the mechanical performance tests of steel strands, wire ropes, chains, welding rods, tapes and components. It is widely used in machinery, metallurgy, transportation, construction engineering, construction materials, colleges and universities, quality inspection and other industries and departments. It has reliable performance, economical and practical, and is an ideal testing machine for material testing in production and engineering.

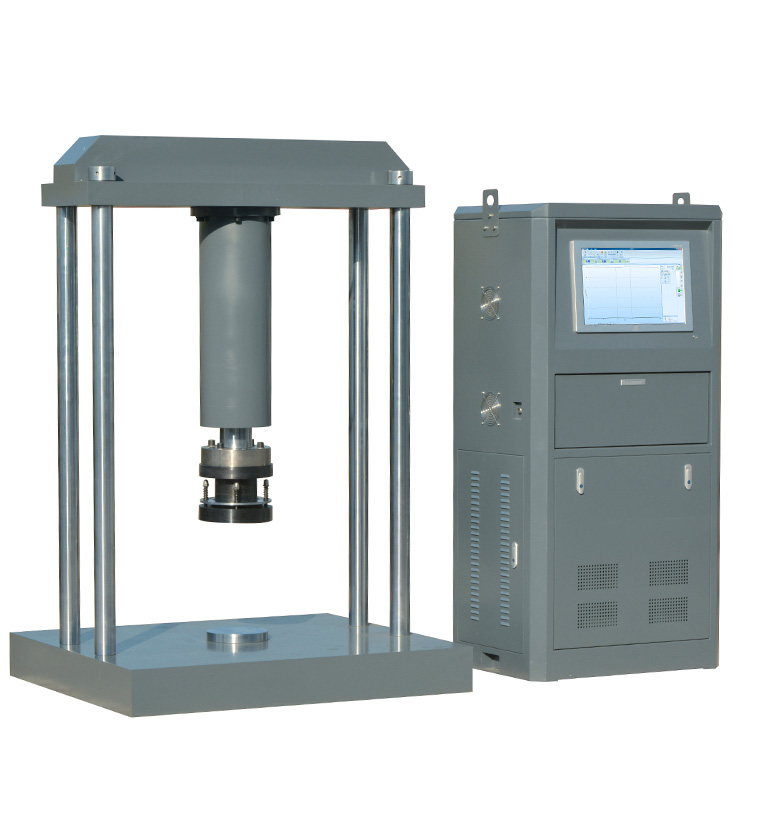

The optical cable winding tester is to test the compressive performance of the material. It can be used for pressure testing of metal and non-metallic materials, concrete, cement, stone bricks and other materials with higher strength. So what factors should be paid attention to when testing materials by the optical cable winding tester?

1. Selection of materials

Before testing, selecting the correct material is a crucial factor for the test machine.

2. Pre-test maintenance

Pay attention to the maintenance of equipment. This step must be operated before the press is used, so as to avoid unnecessary errors. After the equipment is used, the position of each part of the part may be inaccurate, or there are problems with one of the parts of the optical cable winding test machine, which will lead to problems with the equipment during measurement.

3. Maintain the coaxiality of the sample

When measuring samples by optical cable winding test machines, pay attention to maintaining the coaxiality of the samples, because a small error will cause data deviations.

4. Do not operate during operation

During the measurement process of the optical cable winding test machine, remember not to adjust various parameters and auxiliary equipment at will. If other operations are performed during the operation, it will not only affect the experimental results but also reduce the service life of the test machine. In severe cases, the equipment will be scrapped directly, causing unnecessary trouble.

The above is a related introduction to what elements need to be paid attention to when testing materials of optical cable winding test machines. It seems simple, but it cannot be taken into account in the actual process, resulting in inaccurate results of the test. This will affect product quality or product research and development. I hope the above introduction can help you, and at the same time remind you to pay more attention to details when using it, to maximize the protection of the machine, extend the service life and save costs.

Recommended productsPRODUCTS