Company News

Several precautions for tensile testing machines

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Taking ordinary steel with an elastic modulus of 200Gpa as an example, if a material with a gauge distance of 50mm is subjected to tensile tests in the elastic section at a speed of 10mm/min, then the actual stress rate is 200000N/mm2S-1×10mm/min×1min/60S×1/50mm=666N/mm2S-1 general steel yield strength is less than 600Mpa, so it only takes 1 second to pull the sample to yield, which is obviously too fast. Therefore, in the elastic section, stress rate control or load control is generally used. After the sample of material with better plasticity passes through the elastic section, the load does not increase much, and the deformation increases very quickly. Therefore, in order to prevent the tensile speed from being too fast, strain control or beam displacement control is generally used. Therefore, it is recommended in GB228-2002, "In the elastic range and up to the upper yield strength, the separation rate of the test machine chuck should be kept as constant as possible and within the specified stress rate range (material elastic modulus E/(N/mm2) <150000, the stress rate control range is 2-20 (N/mm2) •s-1, material elastic modulus E/(N/mm2) ≥150000, the stress rate control range is 2-20 (N/mm2) •s-1, material elastic modulus E/(N/mm2) ≥150000, the stress rate control range 6-60(N/mm2)•s-1=. If the yield strength is measured only, the strain rate during the yield of the parallel length of the sample should be between 0.00025/s and 0.0025/s. The strain rate within the parallel length should be kept as constant as possible. The strain rate should not exceed 0.0025/s in the plastic range and up to the specified strength (specified non-proportional extension strength, specified total extension strength and specified residual extension strength).

There is a very critical issue here, which is the issue of the switching point between stress velocity and strain velocity. It is to switch between stress velocity and strain velocity at the end of the elastic section. During the switching process, you must ensure that there is no impact or loss of force. This is a very critical technology of the tensile testing machine.

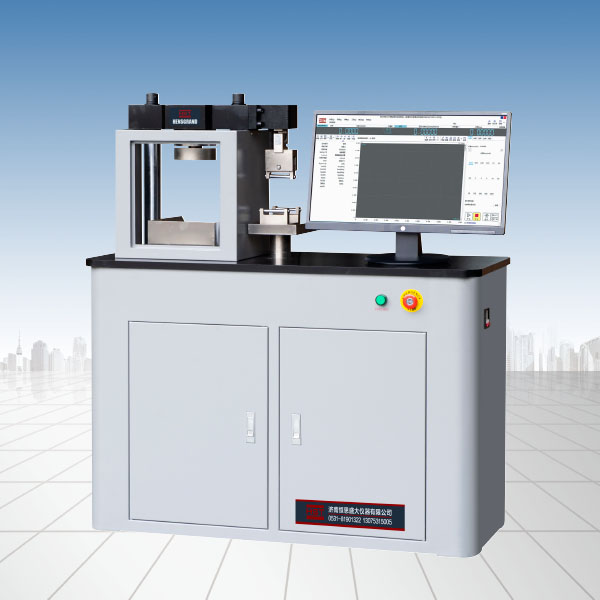

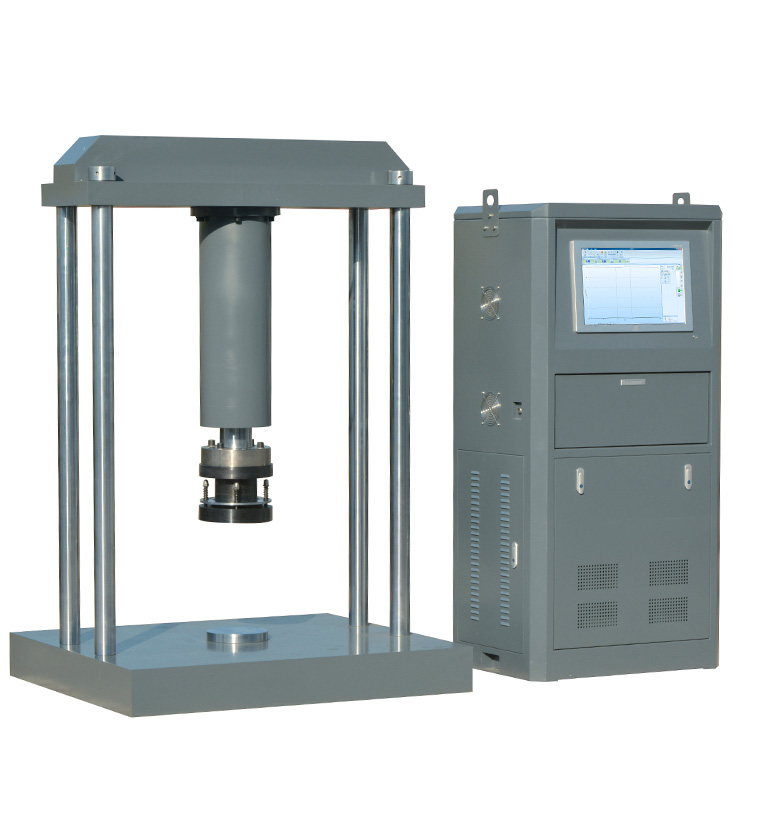

Recommended productsPRODUCTS