Company News

Main functions of electro-hydraulic servo testing machine software

Release time:2018-11-23 source:Jinan Hengsi Shanda Instrument Co., Ltd. Browse:

Electro-hydraulic servoTesting machineThe instruments and equipment specialized in Jinan Hengsi Shanda Instrument Co., Ltd. are the following information about the introduction of electro-hydraulic servo testing machine software by our company.

High-precision American force transmission sensor: 0~5000N (20ton). The force accuracy is within ±0.5%. Capacity segmentation: Seven gears throughout the journey: × 1, × 2, × 5, × 10, × 20, × 50, × 100 adopts high-precision 24 bits A/D, sampling frequency 200Hz, full-process strength resolution 1/1000,000 Power system: Japanese Panasonic AC servo motor + Panasonic AC drive + German planetary reducer + ball screw + bar linear bearing + synchronous belt transmission. Control system: Pulse Command control method is used to make the control more precise. Speed control range is 0.001~1000 mm/min. The adjustment of the Zoom Plate has fast rough adjustment and slow fine adjustment functions. After testing, it will automatically return to the origin and automatically store it. Data transmission method: RS232 transmission display method: UTM107+WIN-XP test software computer screen display. A simple, one-stage and precision seven-stage force linear dual correction system. The luxury test interface software can realize control modes such as fixed speed, positioning shift, fixed load (can set holding time), fixed load increase rate, fixed stress increase rate, fixed strain increase rate and other control modes, plus multi-order control modes can meet different testing requirements. Test space: The test width is about 350 mm (standard specification) The connecting board walking space is 950 mm (excluding fixtures) (standard specification) The full displacement is: The encoder is 2500 P/R, and the accuracy is improved by 4 times. The LINE DRIVE encoder has strong anti-interference ability and is highly displaced analysis of 0.001mm. Small deformation: metal extensometer, analysis 0.001mm (optional) safety device: overload emergency shutdown device, up and down stroke limit device, leakage automatic power outage system, automatic breakpoint shutdown function. Manual control method: Wireless remote control device or manual operation box can be added. Modular function of test standards: Provides test standards settings for users to set the required applications, covering GB, ASTM, DIN, JIS, BS, etc. Test standard specifications. Test sample information: Provide users to set all test sample data and input data at once and use it repeatedly. The electro-hydraulic servo tester can also repair the formulas themselves to improve the fit of the test data. Dual report editing: Fully open user editing reports, for testers to select their favorite reports (the test program has added a built-in EXCEL report editing function to expand the pattern of previous single professional reports). Each length, force unit, and display digits are dynamically swapped, with force units T, Kg, N, KN, g, lb, and deformation units mm, cm, and inch. Auto Scale allows graphics to be displayed in scale. And it can switch dynamically in real-time graphics during testing. It has load-displacement, load-time, displacement-time, stress-strain load-2 point extension diagram, and multi-curve comparison. The test results can be output in EXCEL format data. After the test, it can be automatically archived and manually archived. After the test is completed, the strength, upper and lower yield strength, hysteresis ring method, stepwise approximation method, non-proportional extension strength, tensile strength, compressive strength, fixed elongation strength at any point, fixed load extension at any point, elastic modulus, elongation, peeling interval value, small value, average value, net energy, foldback energy, total energy, bending modulus, breakpoint displacement, x% load, breakpoint load X% displacement, etc. Data backup: Test data can be saved in any hard disk partition. Random switching of multiple languages: Simplified Chinese, Traditional Chinese, and English. The software has historical test data demonstration function.

MoreMaterial testing machineAll information is available at Jinan Hengsi Shanda Instrument Co., Ltd.

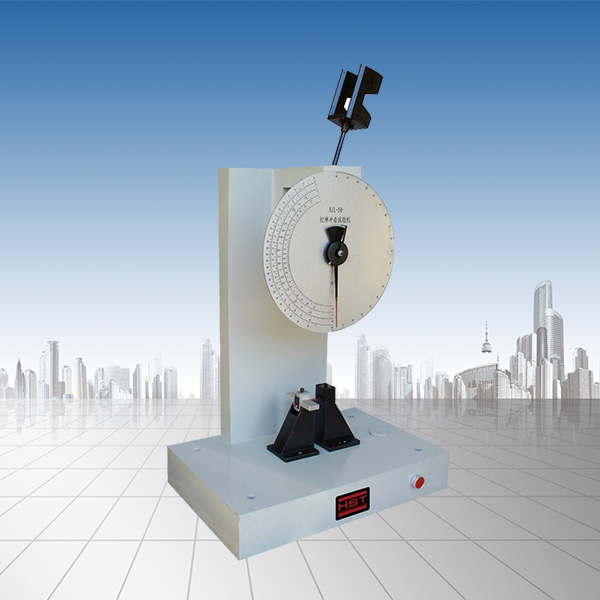

- Previous article:Introduction to the function of impact specimen notch pulling bed

- Next article:3 aspects to know when purchasing a test machine

Recommended productsPRODUCTS