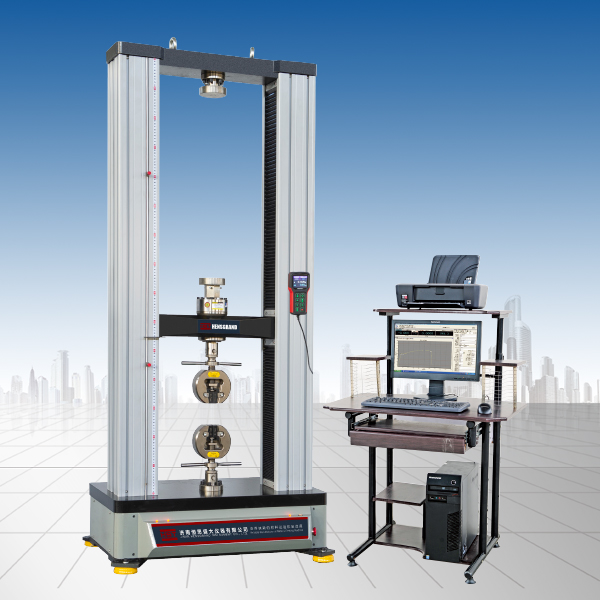

Microcomputer-controlled plastic-clad steel belt tensile test machine

Microcomputer-controlled plastic-clad steel belt tensile test machine

Product Classification: Electronic universal testing machine series

Product Overview:This machine can conduct mechanical properties testing and analysis research on metal, non-metal and composite materials, and is widely used in aerospace, petrochemical, mechanical manufacturing, plastic rubber, ceramic building materials, metal materials, construction engineering and other industries, as well as universities, scientific research institutions, technical supervision, quality inspec

Main uses

This machine can conduct mechanical properties testing and analysis research on metal, non-metal and composite materials, and is widely used in aerospace, petrochemical, mechanical manufacturing, plastic rubber, ceramic building materials, metal materials, construction engineering and other industries, as well as universities, scientific research institutions, technical supervision, quality inspection stations and other departments.

Different accessories can be selected according to GB/ISO/ASTM/JIS/DIN and other standards, and can be stretched, compressed, bending, peeled, sheared, tear, punctured, and top-breaking. The yield strength, tensile (pressure, bending) strength, elongation, non-proportional strength, elastic modulus and other parameters of the material can be detected.

The control system software adopts the WINDOWS operating system as a platform, and has the characteristics of fast running speed, gentle interface and simple operation, which can meet the test and measurement needs of different materials. If there are special requirements, the software can be customized and the software functions can be expanded according to user requirements.

Measurement system:

Load measurement: 0.05%FS high stability, high-precision spoke-type tensioning sensor is adopted, and a high-performance measurement and amplification system is equipped to ensure high resolution of the test force.

Sample deformation measurement: Through a large deformation measurement system or electronic extension meter (small deformation measurement), a 24-bit A/D conversion microcontroller acquisition system is used, and the computer-controlled data processing is used to realize the deformation measurement of the sample.

Displacement measurement: The 2000P/R high-precision photoelectric encoder is used to rotate coaxially with the precision lead screw, and the measurement of the displacement (i.e., the relative displacement of the upper and lower chucks) is achieved through a digital circuit.

Transmission control system

The machine adopts a dual-space door structure, with the upper space stretched and the lower space compressed and bent. The main machine part consists of a gantry frame composed of columns, upper beams, middle beams and workbenches. The speed control system is installed at the lower part of the workbench. The servo motor with high speed control accuracy, wide range and stable performance drives the ball screw pair to rotate through the synchronous toothed belt reduction system. The ball screw pair drives the middle beam, driving the tensile attachment (or compression and bending attachments) to move up and down, realizing the loading and unloading of the sample. This structure has the advantages of high stiffness, high efficiency, and stable transmission.

Test force control system

It adopts computers combined with advanced electronic technology to achieve standardization and unitary control, and has the characteristics of stable loading, accurate measurement and high acquisition frequency. Automatically collect and process test data, draw multiple curves and print test reports.

Protection device

It has protection functions such as overload, overcurrent, and leakage.

Product Name | Microcomputer-controlled plastic-clad steel belt tensile testing machine (gantry frame structure) | ||||||

Product model | WDW-5 | WDW-10 | WDW-20 | WDW-50 | WDW-100 | ||

Structural form | Gate structure | ||||||

Testing Force (KN) | 5 | 10 | 20 | 50 | 100 | ||

Testing force level | Level 1 | ||||||

Test force measurement range | 2%--100%FS | ||||||

Relative error of test force display value | ≤±1% of the displayed value | ||||||

Force resolution | 1/300000 | ||||||

Displacement measurement device | Optoelectronic encoder | ||||||

Relative error of displacement display value | ≤±1% of the displayed value | ||||||

Displacement resolution (mm) | 0.01 | ||||||

Displacement rate adjustment range (mm/min) | 0.05-500 Wuji speed adjustment | 0.05-300 Wuji speed adjustment | |||||

Safety protection device | Mechanical limit protection and software overload protection | ||||||

Effective stretching space (mm) | 800 | 700 | 650 | ||||

Effective compression space (mm) | 750 | 650 | 600 | ||||

Effective test width (mm) | 350 | 400 | 450 | ||||

Wedge-shaped fixture clamping method | Manually tighten | ||||||

Compression attachment (mm) | Pressure plate diameter φ120 or customized | ||||||

Host size (mm) | 690×380×1650 | 690×380×1650 | 690×380×1650 | 755×355×1780 | 825×600×1950 | ||

Host power supply | 0.5KW/AC220V±10% | 0.5KW/AC220V±10% | 0.5KW/AC220V±10% | 0.75KW/AC220V±10% | 1KW/AC380V±10% | ||

Host weight (KG) | 320 | 320 | 340 | 420 | 560 | ||

(The above parameters are for reference only, and the detailed parameters are mainly real equipment)

- Previous article:Digitally explicit plastic-clad steel belt tensile testing machine

- Next article:Microcomputer-controlled geotight tester

Recommended informationNEWS

- [2025-06-11]How to maintain and maintain the test machine

- [2025-06-11]Faced with a fiercely competitive market, what should China's lock industry make adjustments?

- [2025-05-20]Gate terminal tensile testing machine

- [2025-05-20]How to install and operate the tensile tester

- [2025-04-09]A list of test standards for rubber and its products

- [2025-04-09]Explanation of 9 test items of wire tension testing machine

- [2025-03-25]Common obstacles and methods for e-tension testing machines

- [2025-03-25]What should be paid attention to when operating and testing the impact test machine?

- [2025-03-20]Find different plastic test

- [2025-03-20]Characteristics and types of electro-hydraulic servo systems

- [2025-03-14]Process Standards of Tensile Testing Machine

- [2025-03-14]Test machine repair, test machine failure

- [2023-11-28]Hengsi Electronic Universal Testing Machine Hydraulic Universal Testing Machine Loading and Delivering

- [2023-11-27]Functions of electronic universal testing machine

- [2023-11-14]Breaking tension of wire rope

- [2023-11-03]Preparation of tensile test specimens of glass fiber woven fabric

- [2023-10-16]Wire and cable tension testing machine

- [2023-09-20]From September 19 to 23, 2023, Shanghai New Materials Industry Exhibition, welcome to visit and exchange at our booth!