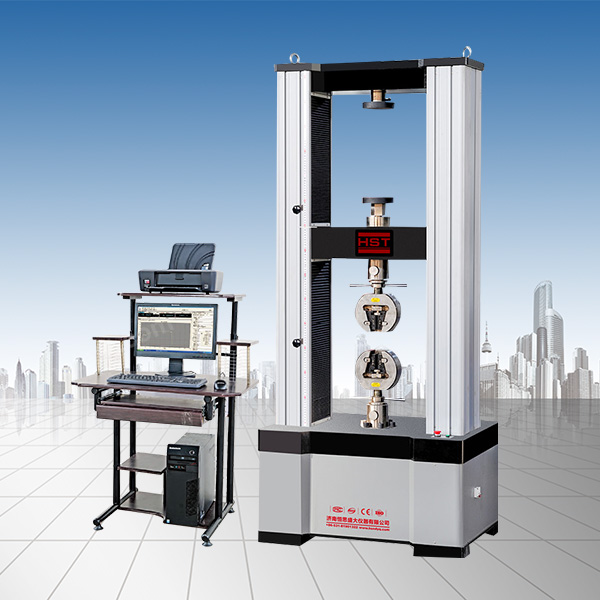

UTM5305X microcomputer controlled electronic universal test machine

UTM5305X microcomputer controlled electronic universal test machine

1. Product overview of UTM5305X microcomputer controlled electronic universal test machine:

This machine is an important instrument and equipment for testing the physical, mechanical, process, structural and internal and external defects of various materials and their products. After selecting the corresponding fixture, you can complete the tests of metal or non-metallic materials such as tensile, compression, bending, shearing, peeling, etc.; use high-precision force sensors and high-resolution displacement sensors to ensure accurate measurement; have closed-loop controls such as constant rate loading, constant rate deformation, and constant rate displacement.

This machine is easy to install, simple to operate, and efficient to test; it is widely used in universities, research institutes, testing institutions, aerospace, military industry, metallurgy, machinery manufacturing, transportation construction, construction and building materials industries to conduct precise material research, material analysis, material development and quality control; it can conduct process qualification performance verification tests of materials or products.

2. The design of UTM5305X microcomputer controlled electronic universal test machine is based on relevant standards:

GB/T 16491-2008 "Electronic Universal Testing Machine";GB/T 2611-2007 "General Technical Requirements for Testing Machines";

JB/T 7406.1-1994 "Testing Machine Terminology Material Testing Machine";JJG 139-2014 "Tenering, Pressure and Universal Material Testing Machine";

Standard test methods and definitions for mechanical properties test of ASTM A370 steel products,JB/T 6147-2007 "Technical Requirements for Packaging, Packaging Marking, Storage and Transportation of Test Machines";

GB/T 22066-2008 "Evaluation of Computer Data Acquisition System of Static Single-axis Test Machine";

GB/T 16825.1-2008 "Inspection of Static Single-Shape Testing Machine Part 1: Inspection and Calibration of Force Testing System of Tension and (or) Pressure Testing Machine".

three,Main technical parameters of UTM5305X microcomputer controlled electronic universal test machine:

(I) Measurement parameters

Test force (kN): 300;

Test machine level: level 0.5;

Effective measurement range of test force: 0.4%-100%F.S;

Test force measurement accuracy: better than ≤±0.5%;

Displacement measurement resolution: 0.02μm;

Displacement measurement accuracy: better than ≤±0.5%;

Electronic extensometer measurement accuracy: better than ≤±0.5%;

Force resolution: 1/520000;

(II) Control parameters:

Control methods: force closed-loop control, deformation closed-loop control, displacement closed-loop control;

(III) Host parameters:

Number of columns: 6 columns (4 columns, 2 lead screws), single space structure;

Maximum compression space (mm): 800;

Maximum stretching spacing (mm): 800;

Effective span (mm): 600;

Workbench size (mm): 1050×660;

(IV) Hydraulic follow-up oil source parameters:

Main system pressure (Mpa): 25;

Height from the ground (mm): 780;

Material and color of the operating countertop: solid psychological board, black;

Fuel tank capacity (L): 50.

(V) Attached parameters:

Clamping method: built-in wedge type hydraulic automatic clamping;

Jaw size (mm): height 90×width 90;

Clamping range of circular specimen (mm): Φ6-Φ13; Φ13-Φ26; Φ26-Φ40;

Plate sample clamping thickness (mm): 0-15, 15-30;

Maximum clamping width of plate specimens (mm): 90;

Size of upper and lower press plate (mm): Φ180.

(VI) Parameters of the whole machine:

Host dimensions (mm): 1102*870*2395;

Host weight (kg): 2200;

Power, voltage, frequency: 380V/50Hz;

Recommended informationNEWS

- [2022-09-09]How to choose the internal structure of the tensile tester

- [2022-09-02]Daily maintenance of test machines

- [2022-09-02]Research and development trends of spring test machines

- [2022-09-02]Working principle of anchor chain tension testing machine

- [2022-08-26]Advantages of universal tensile testing machine

- [2022-08-26]Do you know how important the configuration of the universal tensile test machine is? The configuration of the universal tensile test machine

- [2022-08-26]Introduction to the functions of the repeated bending test machine of metal material

- [2022-08-26]How to use the universal tensile testing machine?

- [2022-08-26]What are the key points of the lateral deformation test of electronic universal testing machines?

- [2022-08-12]Testing method of metal rods by testing machine

- [2022-08-12]Electronic universal testing machine-Plastic film tensile testing machine

- [2022-08-04]How to install a clamp to save effort

- [2022-08-04]What are the causes of oil leakage in the universal pressure test machine?

- [2022-08-04]Tension machine

- [2022-07-29]Staff must conduct necessary inspections on the different structures and parts of the fatigue testing machine

- [2022-07-29]In practical applications, friction between parts is inevitable.

- [2022-07-29]Methods to avoid positioning errors of electronic universal test machines

- [2022-07-29]What errors are prone to occur when using the fatigue test machine