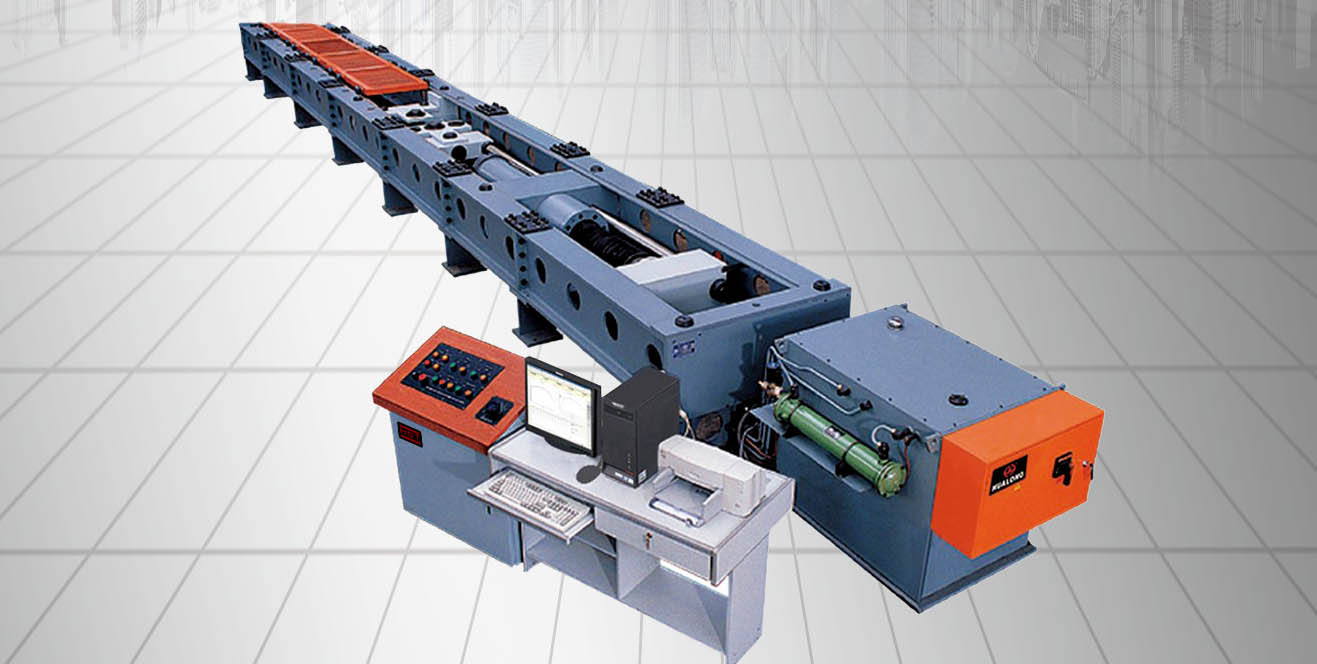

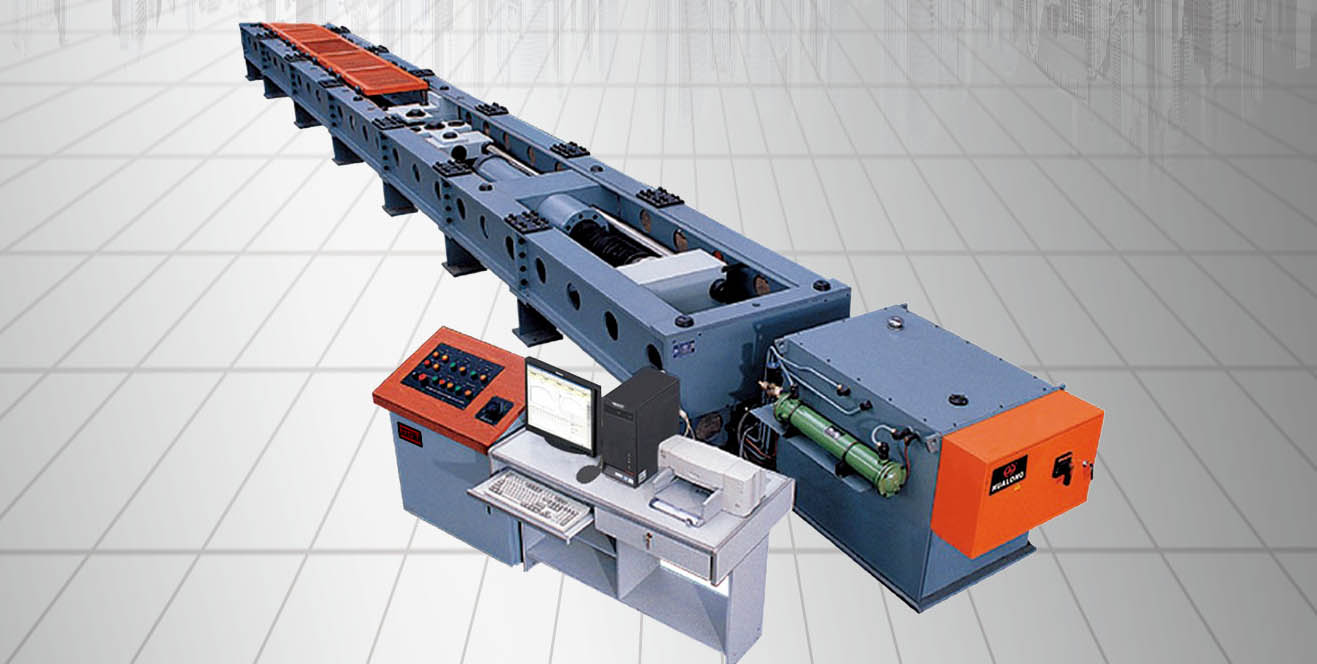

Microcomputer screen display horizontal tensile testing machine WEL series

Microcomputer screen display horizontal tensile testing machine WEL series

Purpose and features:

ShouldTesting machineIt is mainly used for tensile performance tests of various metal components, steel cables, chains, anchor chains, hoisting belts, cables, separation discs, etc.

The main part of the test machine adopts a steel plate welded frame structure, a sectioned mobile beam adjusts the test space, a single rod double-acting piston cylinder applies the test force, and a manual control of the test process, and a load sensor test force, and a microcomputer displays the test force and test curve.

Main technical parameters:

name | Microcomputer screen display horizontal tensile testing machine |

model | WEL-600, 1000, 2000, 3000 |

Testing force (kN) | 600, 1000, 2000, 3000 |

Test force measurement range | 4%~100%FS |

Test force measurement accuracy | ±1% |

Displacement display error | ±1% |

Tensile distance (excluding piston stroke) | 0--10000mm, can be made according to the user's request. |

Cylinder stroke | 500mm (can be made according to user requirements) |

Sample clamping method | Standard is a pin, and hydraulic clamping can also be used as required. |

Test machine effective space | The width is 750mm, and can be made according to the user's request. |

Control test method | Hand valve control test process, microcomputer displays test force and test curve, microcomputer servo automatic control, or manual valve control |

Trend space adjustment method and interval | Hand-push or electric adjustment; adjustment spacing is 500mm; |

Fixing method of moving beams | Manual latch fixation or hydraulic automatic latch fixation |

Computer configuration | Lenovo brand computer |

Printer configuration | HP A4 format color inkjet printer |

Software Configuration | 1 set of test software under the WINDOWSXP platform |

Power supply voltage | The conventional voltage is 220V/380V, and can also be configured according to the standard voltage of the country where the use is used. |

Product Features

(1) Control unit: The control system is a computer software and hardware technology, combined with semiconductor technology, which is reliable, advanced, easy to operate and flexible in measuring force, displacement, deformation and speed control.

(2) Microcomputer system: Lenovo brand microcomputer is used as the host to complete the functions of setting the whole machine test, data acquisition, computing processing, displaying the printing test results, etc.; it is equipped with the KQL-PowerTest2001 Chinese and English version intelligent testing software package for the test machine, which can measure and judge various performance parameters of various material tests based on national standards, international standards or standards provided by users, and calculate and process the data; then output test reports and test curves in various required formats.

(3) Safety protection: The equipment is equipped with mechanical limit protection, automatic overload shutdown protection, automatic overcurrent and leakage power outage protection, emergency switch and other protection functions.

(4) Safety protection: A mesh safety protection net is installed in the test area. The protection net can be easily pushed and pulled and opened, which is convenient, safe and reliable.

Advantages of the product

(1) Use a spoke-type load sensor, with high accuracy and stable performance;

(2) Italian imported oil pump unit with low noise and stable oil circuit without impact;

(3) Hydraulic seal adopts a double seal structure to effectively prevent oil leakage and oil leakage;

(4) The force-pressure cross beam connected to the piston head is equipped with a moving car, reducing various mechanical frictions.

(The above parameters are for reference only, and the detailed parameters are mainly real equipment)

- Previous article:JBW-800 pendulum impact tester

- Next article:Electro-hydraulic anti-flexural compression test machine (100KN)

Recommended informationNEWS

- [2022-10-21]We need to check this problem when there is this problem with the rubber tensile tester

- [2022-10-21]Let me tell you about the operating procedures of the impact test low temperature tank

- [2022-10-21]Let me tell you about the installation requirements of the electro-hydraulic servo universal test machine

- [2022-10-21]Methods for daily maintenance of fatigue testing machines

- [2022-10-14]Basic knowledge and performance inspection of carbon fiber cloth

- [2022-10-14]Basic knowledge and performance inspection of rebar

- [2022-10-14]Daily maintenance and maintenance of electronic universal testing machines

- [2022-09-30]Classification and performance differences of material testing machines

- [2022-09-28]What issues should be paid attention to when maintaining a hydraulic universal testing machine?

- [2022-09-28]What should be noted when using the repetitive bending test machine for steel bars?

- [2022-09-28]Main uses and daily maintenance of spring tester

- [2022-09-28]How should the pressure tester be operated and calibrated

- [2022-09-22]How should the pressure tester be operated and calibrated

- [2022-09-09]Performance characteristics of insulator horizontal tensile testing machine

- [2022-09-09]Basic functions of terminal tension testing machine

- [2022-09-09]Operation method and characteristics of cup protrusion test machine

- [2022-09-09]Tear test of various samples by electronic universal testing machine

- [2022-09-09]How to choose the internal structure of the tensile tester