What are the common knowledge related to hydraulic universal testing machines? Related knowledge of hydraulic universal testing machine

What are the common knowledge related to hydraulic universal testing machines? Related knowledge of hydraulic universal testing machine

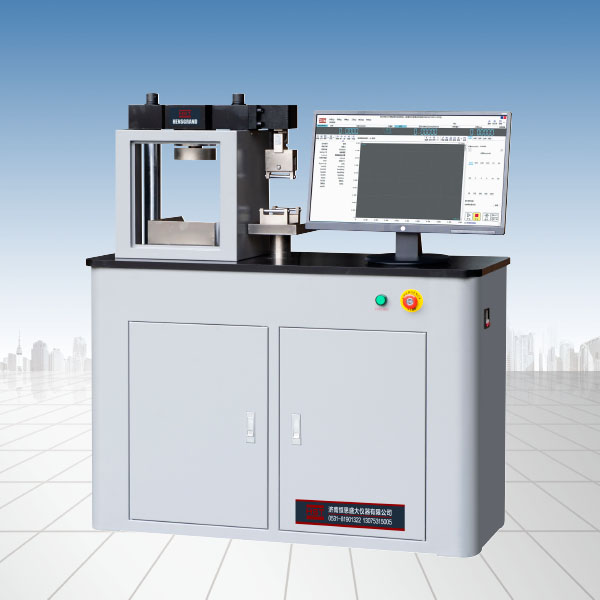

In many fields, hydraulic universal testing machines are required to be installed. The instrument uses different tests such as tensile, bending, and compression to the materials, and the detection range is also very wide. In this chapter, the editor of Fule Instruments will learn about the six basic common sense of this universal test machine with you!

1. The test machine is a highly precise instrument. Whether it is for transportation or installation, it must be strictly implemented in accordance with the prescribed requirements. However, when the test is transported to the specified place, the user must inspect and accept it. If the packaging quality is found to be damaged, you must contact the manufacturer to solve the problem.

2. Nowadays, hydraulic universal testing machines are all equipped with this manual. The overall structure is reasonable and the operation is simple. However, installation still requires familiarity with the instructions to ensure that the staff master the basic operating procedures of the instrument and lay a good foundation for later use.

3. Before installing the test machine, users need to check whether the equipment-related accessories, accessories, clamping samples, etc. all comply with the regulations. If there are any problems, contact the manufacturer in time to solve the relevant problems.

4. Due to the wide range of testing, different materials will often be tested. At this time, the correct testing method needs to be adopted, and the installation regulations and requirements are required to operate according to the shape of the sample.

5. After the work is completed, clean it up appropriately to ensure that there are no residues that affect the next test. During each test, the height, measurement method, time, etc. must be adjusted according to the sample. In addition, it is also necessary to ensure that the oil valve can be closed only if the test is broken, and the oil pump motor of the test machine is stopped. Only when the test is confirmed to stop can the plug be unplugged and the broken sample can be taken for observation, recording and other related data.

Recommended informationNEWS

- [2022-10-27]What should be paid attention to when installing fixtures in tensile testing machine

- [2022-10-27]Maintenance method of friction and wear tester

- [2022-10-21]Electronic universal material testing machine is used for wire tension testing, what is the jaw breakage

- [2022-10-21]We need to check this problem when there is this problem with the rubber tensile tester

- [2022-10-21]Let me tell you about the operating procedures of the impact test low temperature tank

- [2022-10-21]Let me tell you about the installation requirements of the electro-hydraulic servo universal test machine

- [2022-10-21]Methods for daily maintenance of fatigue testing machines

- [2022-10-14]Basic knowledge and performance inspection of carbon fiber cloth

- [2022-10-14]Basic knowledge and performance inspection of rebar

- [2022-10-14]Daily maintenance and maintenance of electronic universal testing machines

- [2022-09-30]Classification and performance differences of material testing machines

- [2022-09-28]What issues should be paid attention to when maintaining a hydraulic universal testing machine?

- [2022-09-28]What should be noted when using the repetitive bending test machine for steel bars?

- [2022-09-28]Main uses and daily maintenance of spring tester

- [2022-09-28]How should the pressure tester be operated and calibrated

- [2022-09-22]How should the pressure tester be operated and calibrated

- [2022-09-09]Performance characteristics of insulator horizontal tensile testing machine

- [2022-09-09]Basic functions of terminal tension testing machine