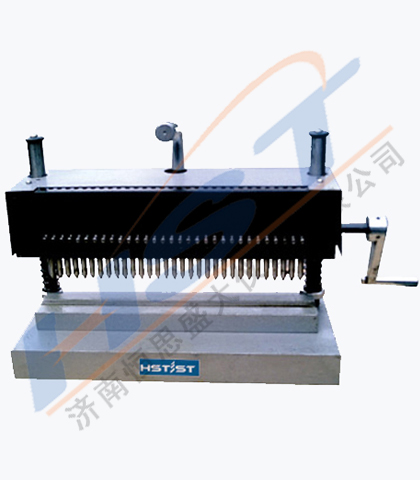

Manual sample gauge (drawing machine)

Manual sample gauge (drawing machine)

Product Classification: Electronic universal testing machine series

Product Overview:The continuous sample gauge produced by our company is made by modifications based on Ansteel drawings. Production specification is 400 model. It is used to mark the specimens of round steel, plates, steel pipes, steel profiles and other nonferrous metal materials for tensile samples. The mechanism is precisely manufactured, easy to use, high work efficiency, accurate handling, and easier to inspe

Functional uses

The continuous sample gauge produced by our company is made by modifications based on Ansteel drawings. Production specification is 400 model. It is used to mark the specimens of round steel, plates, steel pipes, steel profiles and other nonferrous metal materials for tensile samples. The mechanism is precisely manufactured, easy to use, high work efficiency, accurate handling, and easier to inspect and repair.

Technical parameters

1) Every time you shake for one week, you can mark 40 punctuation points in succession.

2) The punctuation distance is 10mm or 5mm, and the error does not exceed ±0.15mm. The punctuation needle is made of ball bearing steel, and the hardness is not less than HRC55 degrees.

Easy to use

When in use, place the sample material into the sample holder slot, and adjust the wire master seat according to the length and size of the sample material, and adjust the sample seat according to the length and size of the sample. Unscrew the fixing screws on the sample holder to move the sample holder back and forth. According to the requirements of the material, aligning the center of the diameter, shaking it with your right hand, grasping the handle with your left hand until the punctuation needle tip touches the sample material, and press it slightly tightly, and shake the handle clockwise with your right hand for one week.

Our factory has vulnerable accessories, punctuation needles and springs, which can be purchased at any time when you call. If this machine does not meet the technical requirements and is damaged due to quality, the company will be responsible for free repair and replacement.

(The above parameters are for reference only, and the detailed parameters are mainly real equipment)

- Previous article:Wire and cable tension testing machine

- Next article:Electric sample gauge (drag machine)

Recommended informationNEWS

- [2022-11-30]What is the maintenance of the impact test machine?

- [2022-11-04]Standard impact test method for metal material notch specimens

- [2022-11-04]1000KN digital display manhole cover pressure tester

- [2022-11-04]Rubber material tensile testing machine

- [2022-10-27]What should be paid attention to when installing fixtures in tensile testing machine

- [2022-10-27]Maintenance method of friction and wear tester

- [2022-10-21]Electronic universal material testing machine is used for wire tension testing, what is the jaw breakage

- [2022-10-21]We need to check this problem when there is this problem with the rubber tensile tester

- [2022-10-21]Let me tell you about the operating procedures of the impact test low temperature tank

- [2022-10-21]Let me tell you about the installation requirements of the electro-hydraulic servo universal test machine

- [2022-10-21]Methods for daily maintenance of fatigue testing machines

- [2022-10-14]Basic knowledge and performance inspection of carbon fiber cloth

- [2022-10-14]Basic knowledge and performance inspection of rebar

- [2022-10-14]Daily maintenance and maintenance of electronic universal testing machines

- [2022-09-30]Classification and performance differences of material testing machines

- [2022-09-28]What issues should be paid attention to when maintaining a hydraulic universal testing machine?

- [2022-09-28]What should be noted when using the repetitive bending test machine for steel bars?

- [2022-09-28]Main uses and daily maintenance of spring tester