Current location:front page >> Product Center >> Electronic universal testing machine series >> Digitally explicit electronic universal testing machine

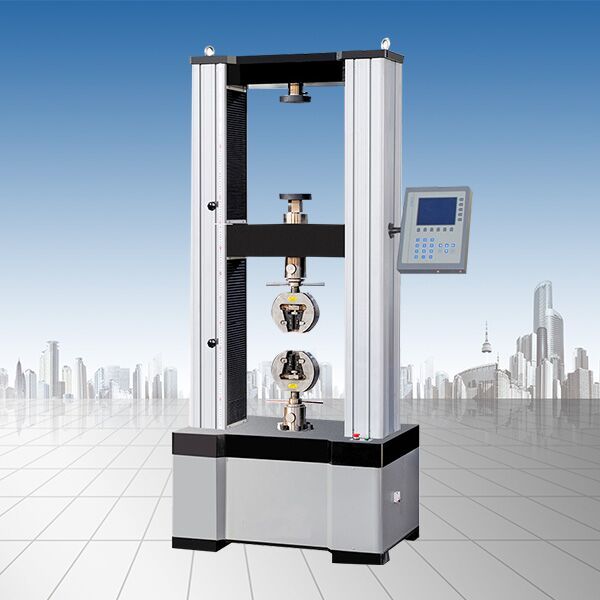

WDW-S digitally explicit electronic universal test machine (gantry)

WDW-S digitally explicit electronic universal test machine (gantry)

Product Classification: Digitally explicit electronic universal testing machine

Product Overview:This machine can conduct mechanical properties testing and analysis research on metal, non-metal and composite materials, and is widely used in aerospace, petrochemical, mechanical manufacturing, plastic rubber, ceramic building materials, metal materials, construction engineering and other industries, as well as universities, scientific research institutions, technical supervision, quality inspec

Main uses

This machine can conduct mechanical properties testing and analysis research on metal, non-metal and composite materials, and is widely used in aerospace, petrochemical, mechanical manufacturing, plastic rubber, ceramic building materials, metal materials, construction engineering and other industries, as well as universities, scientific research institutions, technical supervision, quality inspection stations and other departments.

Different accessories can be selected according to GB/ISO/ASTM/JIS/DIN and other standards, and can be used for tensile, compression, bending, peeling, shear, tearing, puncture, top breaking and various high and low temperature tests. The yield strength, tensile (pressure, bending) strength, elongation, non-proportional strength, elastic modulus and other parameters of the material can be detected.

Host structure

The machine adopts a dual-space door structure, with the upper space stretched and the lower space compressed and bent. The main machine part consists of four columns, upper beam, middle beam and workbench. The speed control system is installed at the lower part of the workbench. The servo motor with high speed control accuracy, wide range and stable performance drives the ball screw pair to rotate through the synchronous toothed belt reduction system. The ball screw pair drives the middle beam, driving the tensile attachment (or compression and bending attachment) to move up and down, realizing the loading and unloading of the sample. This structure has the advantages of high stiffness, high efficiency, and stable transmission.

Comprehensive testing platform

As a hardware platform, this microcontroller collects and processes data accurately and accurately, has a gentle measurement and control interface, clear intuitive levels, and simple operation.

Test force measurement:

Load measurement: High-precision spoke-type load sensor is selected and equipped with a high-performance measurement and amplification system to ensure high resolution of the test force. Multiple sensors can be configured according to user needs to achieve measurement of a wide range of test forces.

Displacement measurement: Use 2000P/R high-precision photoelectric encoder to rotate coaxially with precision lead screws, and measure bits are achieved through digital circuits.Power control system

It adopts a fully digital servo controller to control a high-performance servo motor to drive a synchronous toothed belt, driving two pairs of high-precision, clearance-free precision lead screw transmission, which has the characteristics of stable loading, good low speed performance, no gap, high transmission efficiency, low noise and stable transmission.

Deformation measurement system

Large deformation measurement system can be selected according to the requirements of the test standards

Protection device

According to different tests, the limit protection switch position can be adjusted to effectively prevent the fixture from colliding.

It has protection functions such as overload, overcurrent, and leakage.

Product Name | Digitally explicit control electronic universal test machine (gantry frame structure) | ||||||||

Product model | WDW-5S | WDW-10S | WDW-20S | WDW-50S | WDW-100S | ||||

Structural form | Gate structure | ||||||||

Testing Force (KN) | 5 | 10 | 20 | 50 | 100 | ||||

Testing force level | Level 1 | ||||||||

Test force measurement range | 2%--100%FS | ||||||||

Relative error of test force display value | ≤±1% of the displayed value | ||||||||

Force resolution | 1/500000 | ||||||||

Displacement measurement device | Optoelectronic encoder | ||||||||

Relative error of displacement display value | ≤±1% of the displayed value | ||||||||

Displacement resolution (mm) | 0.01 | ||||||||

Displacement rate adjustment range (mm/min) | 0.05-500 Wuji speed adjustment | ||||||||

Safety protection device | Mechanical limit protection and software overload protection | ||||||||

Effective stretching space (mm) | 650 | ||||||||

Effective compression space (mm) | 600 | ||||||||

Effective test width (mm) | 350 | 350 | 350 | 400 | 450 | ||||

Wedge-shaped fixture clamping method | Manual tightening/hydraulic automatic tightening | ||||||||

Compression attachment (mm) | Pressure plate diameter φ120 or customized | ||||||||

Host size (mm) | 690×380×1650 | 690×380×1650 | 690×380×1650 | 755×355×1780 | 825×600×1950 | ||||

Host power supply | 0.5KW/AC220V±10% | 0.5KW/AC220V±10% | 0.5KW/AC220V±10% | 0.75KW/AC220V±10% | 1KW/AC380V±10% | ||||

Host weight (KG) | 320 | 320 | 340 | 420 | 560 | ||||

(The above parameters are for reference only, and the detailed parameters are mainly real equipment)

Recommended informationNEWS

- [2022-11-30]Electronic tensile testing machine

- [2022-11-30]What is the maintenance of the impact test machine?

- [2022-11-04]Standard impact test method for metal material notch specimens

- [2022-11-04]1000KN digital display manhole cover pressure tester

- [2022-11-04]Rubber material tensile testing machine

- [2022-10-27]What should be paid attention to when installing fixtures in tensile testing machine

- [2022-10-27]Maintenance method of friction and wear tester

- [2022-10-21]Electronic universal material testing machine is used for wire tension testing, what is the jaw breakage

- [2022-10-21]We need to check this problem when there is this problem with the rubber tensile tester

- [2022-10-21]Let me tell you about the operating procedures of the impact test low temperature tank

- [2022-10-21]Let me tell you about the installation requirements of the electro-hydraulic servo universal test machine

- [2022-10-21]Methods for daily maintenance of fatigue testing machines

- [2022-10-14]Basic knowledge and performance inspection of carbon fiber cloth

- [2022-10-14]Basic knowledge and performance inspection of rebar

- [2022-10-14]Daily maintenance and maintenance of electronic universal testing machines

- [2022-09-30]Classification and performance differences of material testing machines

- [2022-09-28]What issues should be paid attention to when maintaining a hydraulic universal testing machine?

- [2022-09-28]What should be noted when using the repetitive bending test machine for steel bars?